Development of Hybrid Yarn Structures from Carbon, Stainless Steel, and Elastomer Fibers for Composite Applications

Fasern Garne Composites Recycling Nachhaltigkeit

Zusammenfassung

As part of the IGF research project 01IF22916N, a complete, industry-ready process chain for producing three-component hybrid yarns from rCF, MF, and EF was successfully developed at the ITM of TU Dresden. The process chain comprises fiber preparation, carding, and drafting to form slivers, followed by modified flyer spinning to produce hybrid yarns.

Proof of concept was provided through the production of hybrid yarns with defined fiber volume contents and a functional demonstrator. Fig. 3 illustrates the full process chain from fiber preparation to demonstrator production from rCF, MF and EF at ITM. The resulting yarns ranged from 1500 to 3500 tex and were successfully processed into textile preforms. The resulting composites demonstrated excellent mechanical performance: a maximum flexural strength of 806 ± 18 MPa, flexural modulus of 83 ± 4 GPa, and an impact strength of up to 117 ± 17 kJ/m².

The results show that yarn twist significantly influences composite mechanical properties: moderate twist enhances flexural behavior, while higher twist improves impact resistance. By adjusting the yarn twist level, the mechanical performance of hybrid composites can be effectively tailored.

These novel hybrid yarns are particularly suited for producing cost-efficient, high-performance thermoset composites with complex geometries. Their application-specific performance and process-integrated production offer high innovation and market potential, especially in the fields of materials engineering, lightweight design, sustainability, and resource efficiency. For small and medium-sized enterprises (SMEs) in the textile industry, this technology provides opportunities to develop advanced fiber-reinforced products and establish themselves as key suppliers in sectors such as automotive, mechanical engineering, wind energy, aerospace, medical technology, and sports equipment.

Bericht

Introduction

The size of the CF-CFRP (carbon fiber-reinforced plastics) market was estimated at USD 21.12 billion in 2023. It is projected to grow from USD 22.57 billion in 2024 to USD 38.4 billion by 2032, with a CAGR of approximately 6.86% during the forecast period (2024–2032) [1]. Due to their high specific stiffness and strength, CFRPs are widely used in the automotive, sports, leisure, and aerospace industries [2]. However, CFRP components are brittle under impact loading, which can result in catastrophic failure and severe splintering [3]. This brittleness raises concerns for the use of thermoset CFRP structures in safety-critical components such as wind turbine blades or automotive B-pillars.

Current hybridization concepts aim to combine materials with high stiffness, strength, and ductility [4]. Existing approaches integrate carbon fibers (CF) with stainless steel fibers (MF) or elastomer fibers (EF) using metal or elastomer films in fiber-metal laminates (FMLs), such as CARALL [5–8], or in elastomer-based laminates, such as KRAIBON [9–14]. Metal films offer higher energy absorption due to their plastic deformability and elongation at break of up to 20%, surpassing CFRP and carbon/aramid hybrid composites [15–17]. Elastomer films reduce hazardous splintering under dynamic loading due to their elastic deformation behavior [9]. While such multilayer systems improve impact and splinter resistance, they also carry a high risk of delamination [18]. Moreover, there is a lack of cost-effective and sustainable composites with enhanced impact and splinter properties that fully utilize the benefits of their individual components.

Objective

The goal of this research project was the simulation-based development of novel three-component hybrid yarns with micro-scale hybridization using three distinct material concepts. These yarns were then used to produce functional composite structures for sustainable lightweight applications. By strategically combining ductile metal fibers (MF), highly elastic elastomer fibers (EF), and high-stiffness, high-strength recycled carbon fibers (rCF), scalable composites with tailored mechanical properties were developed.

The developed hybrid yarns form the basis for application-specific composites with high energy absorption capacity and improved damage resistance.

Hybrid Yarn Structures and Related Composites: Development and Characterization

Development and Production of Hybrid Yarns Using Flyer Spinning Technology

Starting from the selected and characterized rCF and EF fiber materials with an average fiber length of 80 mm and defined blend ratios, the fibers were prepared using mechanical pre-opening and blending units. The pre-opened and pre-mixed fibers were processed using a lab-scale carding machine to produce card slivers of rCF and EF. Characterization of these slivers revealed a CF damage level of 10–25%, while EF fibers showed no length reduction.

To avoid damaging the stainless steel fibres during carding, card slivers were firstly produced that were either 100% rCF or a blend of rCF and EF. These were combined with 100% MF slivers to develop sandwich-type structures (rCF/MF or rCF/EF/MF slivers), which served as feed material for the drafting process. The slivers were drafted multiple times to enhance fiber blending and homogeneity. These drafted slivers were then used to produce hybrid yarns.

The ITM’s specialized flyer spinning machine was modified to optimize drafting mechanics, sliver feed, and machine settings to avoid fiber misalignment. Based on experimental investigations, optimal settings were determined, and hybrid yarns with a yarn count of 1500 tex and twist levels ranging from 40 to 150 T/m were produced. These yarns were characterized in accordance with DIN EN ISO 13934-1, evaluating unevenness, yarn structure, and tensile behavior, and were subsequently used to produce composite.

Manufacturing of Recycled Carbon Fiber-Reinforced Composite

Using the developed hybrid yarns, unidirectional (UD) composites were produced via the resin transfer molding (RTM) process. The hybrid yarns were wound under constant tension onto a frame and consolidated under optimized parameters. The resin system consisted of Hexion RIMH 135 and hardener Hexion RIMH 137.

Composite characterization followed standardized test methods. Tensile specimens were prepared based on DIN EN ISO 527-5/A/2, with tensile testing conducted according to DIN EN ISO 527-4. The flexural properties were evaluated in accordance with DIN EN ISO 14125 and impact resistance was assessed using DIN EN ISO 179-2 (Charpy method). The compression-after-impact (CAI) performance was measured following DIN ISO 18352. Additionally, a custom test rig was developed to analyze splintering behavior using a ZwickRoell HTM 5020 high-speed testing machine. Puncture resistance was evaluated according to DIN EN ISO 6603-2.

Selected Results and Discussion

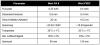

Fig. 1 presents the relationship between flexural strength and modulus for various twist levels in hybrid yarn-based composites at a constant fiber volume content of 50 vol%. Both a CF-filament-based reference composite and three UD composites made from rCF/MF hybrid yarns (90 wt% rCF / 10 wt% MF) were investigated, differing only in yarn twist (40, 80 and 120 T/m). The reference composite achieved 725 ± 35 MPa flexural strength and a modulus of 74 ± 8 GPa. Notably, the T40 hybrid variant surpassed these values, reaching 806 ± 18 MPa and 83 ± 4 GPa, respectively.

However, increasing the yarn twist (80 and 120 T/m) led to a continuous decline in flexural properties. The intensified helical structure reduces fiber alignment in the load direction, which weakens load transfer and overall flexural performance.

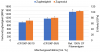

Fig. 2 shows the impact strength of composites made from rCF/MF hybrid yarns at varying yarn twist levels. Results indicate a trend of increasing impact strength with higher twist (40 → 120 T/m), from 85 kJ/m² to 117 kJ/m². This improvement is attributed to a more compact yarn structure, enhanced fiber cohesion, and improved energy absorption during impact. Additionally, the tighter fiber arrangement enhances load transfer and structural integrity by reducing the number of loose fiber ends, resulting in greater resistance to sudden loads.

Summary

As part of the IGF research project 01IF22916N, a complete, industry-ready process chain for producing three-component hybrid yarns from rCF, MF, and EF was successfully developed at the ITM of TU Dresden. The process chain comprises fiber preparation, carding, and drafting to form slivers, followed by modified flyer spinning to produce hybrid yarns.

Proof of concept was provided through the production of hybrid yarns with defined fiber volume contents and a functional demonstrator. Fig. 3 illustrates the full process chain from fiber preparation to demonstrator production from rCF, MF and EF at ITM. The resulting yarns ranged from 1500 to 3500 tex and were successfully processed into textile preforms. The resulting composites demonstrated excellent mechanical performance: a maximum flexural strength of 806 ± 18 MPa, flexural modulus of 83 ± 4 GPa, and an impact strength of up to 117 ± 17 kJ/m².

The results show that yarn twist significantly influences composite mechanical properties: moderate twist enhances flexural behavior, while higher twist improves impact resistance. By adjusting the yarn twist level, the mechanical performance of hybrid composites can be effectively tailored.

These novel hybrid yarns are particularly suited for producing cost-efficient, high-performance thermoset composites with complex geometries. Their application-specific performance and process-integrated production offer high innovation and market potential, especially in the fields of materials engineering, lightweight design, sustainability, and resource efficiency. For small and medium-sized enterprises (SMEs) in the textile industry, this technology provides opportunities to develop advanced fiber-reinforced products and establish themselves as key suppliers in sectors such as automotive, mechanical engineering, wind energy, aerospace, medical technology, and sports equipment.

Acknowledgements

The IGF project 01IF22916N of the research association Forschungskuratorium Textil e.V. was funded via the DLR within the framework of the program for the promotion of industrial collaborative research and development (IGF) by the German Federal Ministry for Economic Affairs and Climate Action, based on a resolution of the German Bundestag. We thank the aforementioned institutions for their financial support.

References

- WiseGuyReports. (n.d.). CF & CFRP Market Report. Accessed on 29.07.2025, https://www.wiseguyreports.com/de/reports/cf-cfrp-market

- E. Witten; V. Mathes; M. Sauer; M. Kühnel: Composites-Marktbericht 2023 - Marktentwicklun-gen, Trends, Ausblicke und Herausforderungen. Deutsche Fachverband für Faserverbundkunststoffe/Composites - AVK, 2023

- J. Striewe; C. Reuter; K.-H. Sauerland; T. Tröster: Manufacturing and crashworthiness of fabric-reinforced thermoplastic composites. Thin-Walled Structures 123(2018), Pp. 501-508. https://doi.org/10.1016/j.tws.2017.11.011

- D. Nestler: Beitrag zum Thema Verbundwerkstoffe - Werkstoffverbunde: Status quo und For-schungsansätze. Chemnitz: Univ.-Verl., 2014. – ISBN 9783944640129

- ZHU, W.; XIAO, H.; WANG, J.; LI, X.: Effect of Different Coupling Agents on Interfacial Properties of Fibre-Reinforced Aluminum Laminates. Materials (Basel, Switzerland) 14(2021)4. https://doi.org/10.3390/ma14041019

- GUPTA, R. K.; MAHATO, A.; BHATTACHARYA, A.: Notch Shape Influence on Damage Evolution of Al/CFRP Laminates Under Tensile Loading: Experimental and Numerical Analysis. Appl Compos Mater (2022). https://doi.org/10.1007/s10443-022-10051-2

- TRZEPIECIŃSKI, T.; NAJM, S. M.; SBAYTI, M.; BELHADJSALAH, H.; SZPUNAR, M.; LEMU, H. G.: New Advances and Future Possibilities in Forming Technology of Hybrid Metal–Polymer Composites Used in Aerospace Applications. J. Compos. Sci. 5(2021)8, Pp. 217 f. https://doi.org/10.3390/jcs5080217

- PONNARENGAN, H.; KAMARAJ, L.; BALACHANDRAN, S. R.; KATHAR BASHA, S.: Evaluation of me-chanical properties of novel GLARE laminates filled with nanoclay. Polym. Compos. 42(2021)8, Pp. 4015-4028. https://doi.org/10.1002/pc.26113

- KRAIBON®: https://www.kraiburg-rubber-compounds.com/kraibon (31.07.2025)

- D. Düring; L. Weiß; D. Stefaniak; N. Jordan; C. Hühne: Low-velocity impact response of composi-te laminates with steel and elastomer protective layer. Composite Structures 134(2015), Pp. 18-26. https://doi.org/10.1016/j.compstruct.2015.08.001

- E. Stelldinger; A. Kühhorn; M. Kober: Experimental evaluation of the low-velocity impact dama-ge resistance of CFRP tubes with integrated rubber layer. Composite Structures 139(2016), Pp. 30-35. https://doi.org/10.1016/j.compstruct.2015.11.069

- E. Sarlin; M. Apostol; M. Lindroos; V.-T. Kuokkala; J. Vuorinen; T. Lepistö; M. Vippola: Impact properties of novel corrosion resistant hybrid structures. Composite Structures 108(2014), Pp. 886-893. https://doi.org/10.1016/j.compstruct.2013.10.023

- LI, Z.; ZHANG, J.; JACKSTADT, A.; KÄRGER, L.: Low-velocity impact behavior of hybrid CFRP-elastomer-metal laminates in comparison with conventional fiber-metal laminates. 02638223 287(2022), Pp. 115340 f. https://doi.org/10.1016/j.compstruct.2022.115340

- FLEISCHER, J. (HRSG.): Intrinsische Hybridverbunde für Leichtbautragstrukturen – Grundlagen der Fertigung, Charakterisierung und Auslegung. Berlin, Heidelberg: Springer Vieweg, 2021. – ISBN 978-3-662-62832-4

- Y. Swolfs; P. De Cuyper; M.G. Callens; I. Verpoest; L. Gorbatikh: Hybridisation of two ductile materials Steel fibre and self-reinforced polypropylene composites. Composites Part A: Applied Science and Manufacturing 100(2017), Pp. 48-54. https://doi.org/10.1016/j.compositesa.2017.05.001

- H.J. Koslowski: Chemiefaser-Lexikon. Deutscher Fachverlag, 2008. – ISBN 3871508764

- H. Schürmann: Konstruieren mit Faser-Kunststoff-Verbunden. Springer-Verlag GmbH, 2007. – ISBN 3540721894

- N. Montinaro; D. Cerniglia; G. Pitarresi: Evaluation of interlaminar delaminations in titanium-graphite fibre metal laminates by infrared NDT techniques. NDT & E International 98(2018), Pp. 134-146. https://doi.org/10.1016/j.ndteint.2018.05.004

Kontakt: mahmud.hossain@tu-dresden.de

Technische Universität Dresden

Fakultät Maschinenwesen

Institut für Textilmaschinen und Textile Hochleistungswerkstofftechnik (ITM)

01062 Dresden

![Abbildung 2: Vergleich der Tiefenbelastung eines Mikrofaserfilters und der Oberflächenfiltration eines Nanofaserfilters [GH04]](/sites/default/files/styles/thumbnail/public/2023-10/Abbildung%202.jpg?itok=ICP_Xj0I)

![Abbildung 3: Elektrospinnanlage Fluidnatek LE-500 mit einem rotierenden Trommelkollektor zur Beschichtung von Substraten. [Sch23]](/sites/default/files/styles/thumbnail/public/2023-10/Abbildung%203.jpg?itok=MqOJl_IW)