Cotton Fibers 2.0: Fireproof and comfortable

A new chemical process developed by Empa turns cotton into a fire-resistant fabric, that nevertheless retains the skin-friendly properties of cotton.

Conventional flame retardant cotton textiles suffer from release of formaldehyde and are uncomfortable to wear. Empa scientists managed to circumvent this problem by creating a physically and chemically independent network of flame retardants inside the fibers. This approach retains the inherently positive properties of cotton fibers, which account for three-quarters of the world's demand for natural fibers in clothing and home textiles. Cotton is skin-friendly because it can absorb considerable amounts of water and maintain a favorable microclimate on the skin.

For firefighters and other emergency service personnel, protective clothing provides the most important barrier. For such purposes, cotton is mainly used as an inner textile layer that needs additional properties: For example, it must be fireproof or protect against biological contaminants. Nevertheless, it should not be hydrophobic, which would create an uncomfortable microclimate. These additional properties can be built into the cotton fibers by suitable chemical modifications.

Durability vs. toxicity

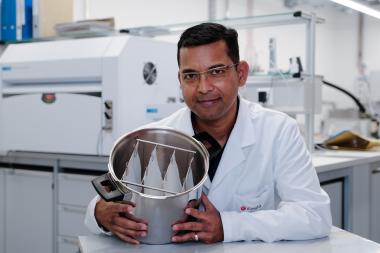

"Until now, it has always taken a compromise to make cotton fireproof," says Sabyasachi Gaan, a chemist and polymer expert who works at Empa's Advanced Fibers lab. Wash-durable flame retardant cotton in industry is produced by treating the fabric with flame retardants, which chemically links to the cellulose in the cotton. Currently, the textile industry has no other choice than to utilize formaldehyde-based chemicals – and formaldehyde is classified as a carcinogen. This has been an unsolved problem for decades. While formaldehyde-based flame retardant treatments are durable, they have additional drawbacks: The -OH groups of cellulose are chemically blocked, which considerably reduces the capability of cotton to absorb water, which results in an uncomfortable textile.

Gaan knows the chemistry of cotton fibers well and has spent many years at Empa developing flame retardants based on phosphorus chemistry that are already used in many industrial applications. Now he has succeeded in finding an elegant and easy way to anchor phosphorous in form of an independent network inside the cotton.

Independent network between cotton fibers

Gaan and his colleagues Rashid Nazir, Dambarudhar Parida and Joel Borgstädt utilized a tri-functional phosphorous compound (trivinylphosphine oxide), which has the capability of reacting only with specifically added molecules (nitrogen compounds like piperazin) to form its own network inside cotton. This makes the cotton permanently fire-resistant without blocking the favorable -OH groups. In addition, the physical phosphine oxide network also likes water. This flame retardant treatment does not include carcinogenic formaldehyde, which would endanger textile workers during textile manufacturing. The phosphine oxide networks, thus formed, does not wash out: After 50 launderings, 95 percent of the flame retardant network is still present in the fabric.

To render additional protective functionalities to the flame retardant cotton developed at Empa, the researchers also incorporated in situ generated silver nanoparticles inside the fabric. This works nicely in a one-step process together with generating the phosphine oxide networks. Silver nanoparticles provide the fiber with antimicrobial properties and survive 50 laundry cycles, too.

A high-tech solution from the pressure cooker

"We have used a simple approach to fix the phosphine oxide networks inside the cellulose," Gaan says. "For our lab experiments, we first treated the cotton with an aqueous solution of phosphorus and nitrogen compounds and then steamed it in a readily available pressure cooker to facilitate the crosslinking reaction of the phosphorus and the nitrogen molecules." The application process is compatible with equipment used in the textile industry. "Steaming textiles after dyeing, printing and finishing is a normal step in textile industry. So it doesn't require an additional investment to apply our process," states the Empa chemist.

Meanwhile, this newly developed phosphorus chemistry and its application is protected by a patent application. "Two important hurdles remain," Gaan says. "For future commercialization we need to find a suitable chemical manufacturer who can produce and supply trivinylphosphine oxide. In addition, trivinylphosphine oxide has to be REACH-registered in Europe."

Contact:

Dr. Sabyasachi Gaan

Advanced Fibers

Phone: +41 58 765 7611

sabyasachi.gaan@empa.ch

Contact:

Prof. Dr. Manfred Heuberger

Advanced Fibers

Phone: +41 58 765 7878

manfred.heuberger@empa.ch

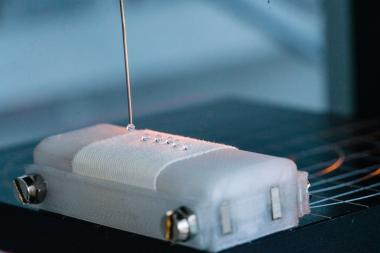

A gel that releases drugs

The novel phosphorus chemistry can also be used to develop other materials, e.g. to make hydrogels that can release drugs upon changes in pH. Such gels could find application in treating wounds that heal slowly. In such wounds, the pH of the skin surface increases and the new phosphorus-based gels can be triggered to release medication or a dye that alerts doctors and nurses to the problem. Empa has also patented the production of such hydrogels.

EMPA, Rainer Klose