Development of bio-based polyethylene fibers for textile applications

In the German research project bioPEtex, BB Engineering (BBE) is working with other partners to develop textiles made from 100% bio-based polyethylene (PE). The aim is to make use of this polymer, which has hardly been used in the chemical fiber industry to date. BBE is contributing its spinning and texturizing expertise and developing the texturing process on an industrial scale. The first promising results are already available – opening up new opportunities for sustainable and economically attractive applications in the textile industry.

For years, the global chemical fiber market has been dominated by PET, a technically mature, versatile, and cost-effective polymer for textile applications. However, despite its advantages in terms of processability, strength, and economic availability, PET has come under criticism: its dependence on fossil raw materials, high CO2 emissions along the value chain, and challenges in recycling PET products are drawing the attention of researchers and industry to alternative materials that are both economical and sustainable.

Biopolymers are an important keyword in this context. However, PET cannot be produced on an industrial scale in a 100% bio-based manner. Clothing made from 100% other biopolymers only exists in studies, as it is too expensive for the mass market. In this context, the German research project bioPEtex is investigating a polymer that, due to its properties, has previously been considered unsuitable for chemical fiber production: polyethylene (PE). This is because bio-based PE is inexpensive to procure and environmentally friendly. However, it has not yet been developed for use in the textile industry.

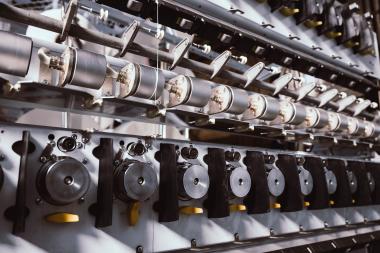

BB Engineering (BBE) is one of the industrial partners working with RWTH Aachen University to implement the project funded by the German Federal Ministry of Research, Technology, and Space. The aim of the project is to develop textiles made from 100% bio-based polyethylene that are both environmentally friendly and economically viable. BBE is a supplier of spinning, texturizing, and recycling equipment as well as extrusion and filtration technology, and supplies customers all over the world. BBE therefore has extensive expertise in the manufacture of synthetic fibers and their return to the recycling cycle. The company is contributing this long-standing expertise to the bioPEtex project. On the one hand, BBE is providing consulting support for the development of the spinning process. On the other hand, BBE is responsible for the crucial process step of texturizing, which has a significant influence on the subsequent textile performance of the developed fibers.

“With our participation in the bioPEtex project, we don’t just want to contribute to the development of sustainable solutions, we also want to focus on the economic benefits for our customers,” explains Dr. Klaus Schäfer, Managing Director of BBE. “Bio-PE textiles offer companies the opportunity to reduce their production costs while tapping into new market segments.”

PE and its role in the chemical fiber industry

PE is one of the most commonly produced polymers worldwide. Particularly durable, hydrophobic, lightweight, and chemically stable, it is used not only in its main area of application, the packaging industry, but also in various other areas such as building materials and consumer goods. However, PE has so far played hardly any role in textile fiber production. From a technical point of view, this is mainly due to processing challenges. PE crystallizes at low temperatures and therefore offers a narrow temperature window for spinning and texturing. In addition, the low polarity of PE makes it difficult to dye.

Today, PE is used exclusively as a functional component in composites, geosynthetics, or special high-performance fibers (e.g., UHMWPE)—but hardly ever in traditional clothing or home textile segments. Yet the material structure also offers properties that are highly attractive for certain textile applications:

- very low density resulting in extremely lightweight fibers,

- excellent chemical resistance,

- very good dimensional stability and abrasion resistance,

- potentially good recyclability due to clear polymer structure,

- water-repellent and quick-drying with a cool feel.

The issue of difficult dyeability could be resolved by spinning dyeing.

As a result, PE could become relevant for applications where lightweight construction, hydrophobicity, robust performance, and recyclability are required—for example, in sports textiles, outdoor products, technical textiles, or hygienic disposable products.

Bio-based PE – Economic and ecological potential for the textile industry

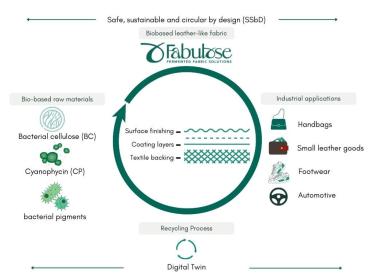

Unlike PET, bio-based PE is chemically identical to its fossil-based counterpart: both materials are completely identical in terms of structure and properties. The only difference lies in the origin of the monomers used. Bio-based PE is usually produced from fermented sugar (e.g. from sugar cane) or starch (e.g. from corn).

Compared to fossil-based PE, it has a significantly better carbon footprint and opens up the possibility of a completely bio-based textile recycling cycle without any loss of quality. Since the low melting point reduces the energy required for processing and (bio)PE is widely available globally, energy and material costs are potentially lower. The textile industry can benefit here from the established raw material flows of the packaging and plastics industries. In addition, the introduction of PE fibers enables the development of new, highly specialized product segments and opens up additional differentiation opportunities for manufacturers through sustainable material alternatives.

BB Engineering develops PE texturizing process

However, before PE can be used on an industrial scale as a material for the chemical fiber industry, it must first be systematically researched and tested. The bio-PEtex project is currently working on this. Within the consortium, BBE is responsible for developing and adapting the texturizing processes. This step is crucial, as it is the texturing that defines the subsequent haptic, functional, and mechanical properties of a fiber. The challenge lies in modifying PE under the novel process conditions in such a way that it becomes compatible with established textile applications.

Overall, the project comprises several innovative steps:

- Material development: Development and production of spinnable bio-PE compounds by TECNARO containing bio-based color pigments.

- Prozess optimization: Melt spinning and false twist texturing processes, which are being scaled up for industrial use at the Institute for Textile Technology at RWTH Aachen University and at BBE.

- Textile production: The partner FALKE is conducting initial knitting trials to validate the yarn in the form of demonstrator T-shirts.

The results so far show promising progress: the bio-PE yarns have suitable mechanical properties and are comfortable to wear with a cooling effect, which is desirable in sportswear, for example. At the same time, a design-for-recycling approach is being pursued in order to efficiently recycle the textiles at the end of their life cycle. A particular milestone in the project is the successful production of a first white t-shirt — a first step toward testing marketability. Further development steps and optimizations are of course still necessary here.

“We are very positive about the results so far. They show that PE has real potential in textile value creation and can offer significant economic and ecological advantages for the industry in specific applications. We are delighted to be involved in this pioneering project. It is our aim to provide our customers with sustainable and profitable innovations,” says Dr. Klaus Schäfer.

BB Engineering BB Engineering GmbH research project RWTH Aachen ITA polyethylene biobased fibers

BB Engineering GmbH