LED Dress Fuses 3D Printing with Futuristic Fashion

- Designer Anouk Wipprecht Collaborates with Chromatic 3D Materials for a Shining, Motion-Activated Display

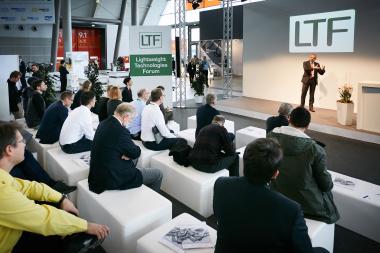

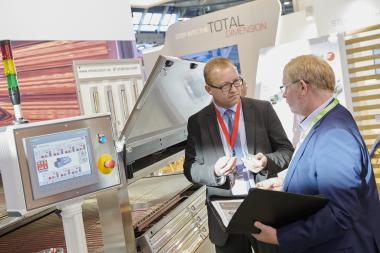

Chromatic 3D Materials, a 3D-printing technology company, and high-tech Dutch fashion designer Anouk Wipprecht have unveiled a new futuristic 3D-printed dress that responds to its environment through LEDs. The motion-activated design is among the first garments in the world to directly embed electronics within 3D-printed elastomers. It highlights what the future of creative expression and social interaction may look like as humankind further integrates with technology. Wipprecht’s design was presented at Formnext, the 3D-printing event in Germany.

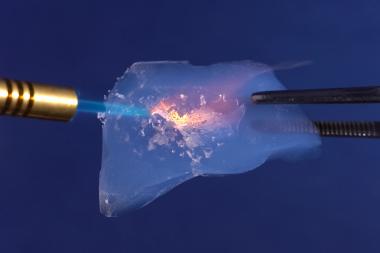

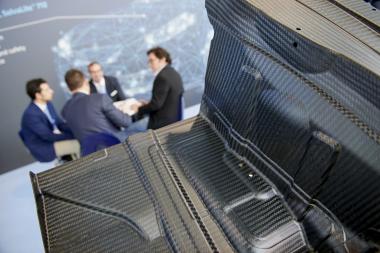

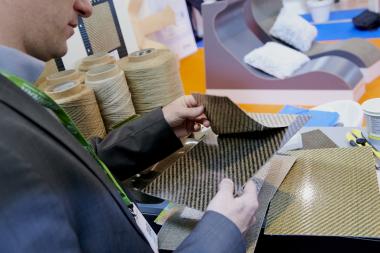

Wipprecht’s avant-garde design highlights the potential of Chromatic’s 3D-printing technology and ChromaFlow 70™ material for commercial use. The designer used 3D printing to adhere nearly 75 flexible, 3D-printed LED domes to the fabric of the dress without adhesive or stitching. That capability could be used to create innovative running apparel, bags, footwear and other products including automotive and aerospace interiors, outdoor recreational equipment and personal protective equipment.

The unique garment also demonstrates the flexibility of Chromatic’s materials. Unlike other 3D-printed materials, which tend to be brittle and hard, the dress features ChromaFlow 70™, a pliable, heat-resistant material that can drape and stretch more than four times its length without breaking. That flexibility makes it suitable for adding soft and seamless structural, functional and aesthetic elements that are useful for intimate and leisure apparel, sportswear, swimwear and other garments where comfort, silhouette and durability are crucial.

"Using Chromatic’s 3D materials to print offers numerous possibilities for the fashion industry. For designers like me, who incorporate electronics into our creations, it provides a unique opportunity of embedding and securing electronic parts within the printing process,“ says Anouk Wipprecht. “This is my most wearable — and washable — 3D-printed dress yet! As the electronics are enclosed, the material allows me to diffuse my LED lights, and the elastomer is both flexible and strong — making it excellent to bond to fabrics.”

“This collaboration is more than a partnership — it's a vision coming to life. By merging the genius of Anouk Wipprecht with our innovative 3D printing, we're setting the precedent for the future of fashion. We are embarking on a journey that amplifies the boundless integration of tech and art, opening doors for endless possibilities and applications in textiles and fashion,” said Cora Leibig, founder and CEO of Chromatic 3D Materials.

Chromatic 3D Materials