COLLECTION REPORT MENSWEAR AUTUMN/WINTER 2020 CONTEMPORARY CLASSICS

FLUID IDENTITIES

Digitale Medien und globale Vernetzung verändern den Aggregatzustand der Gesellschaft, lösen eingefahrene Strukturen und schaffen Raum für flexible Lebensentwürfe. Themen wie Work-Life-Balance und Vorstellungen von privatem Glück lassen sich heute genauso wenig in Schablonen pressen wie Gender-Definitionen oder politische Haltungen. Auch die großen globalen Themen befinden sich im Stadium permanenter Fluktuation und verlangen nach einer radikalen Neuausrichtung von Wirtschaft und Gesellschaft, bei der gewohnte Konsumgewohnheiten durch mehr soziale Verantwortung und eine neue Art des Verbrauchens ersetzt werden. Aus der Notwendigkeit sich klar zu positionieren, ist inzwischen eine globale Bewegung entstanden. Sie zeigt, dass auch ein einzelnes Individuum mit der richtigen Idee im großen Maßstab Zukunft gestalten kann. Das eigene Handeln permanent zu hinterfragen und flexibel auf veränderte Gegebenheiten zu reagieren, hat auch den Umgang mit Mode grundlegend verändert. Trageanlässe und Gender-Rollen sind immer weniger ein Kriterium für das konsumieren von Mode. Heute geht es vielmehr darum, Verführung und Verantwortungsbewusstsein in die richtige Balance zu bringen und daraus einen neuen Optimismus der Veränderung entstehen zu lassen.

Diese Zeitgeist-Aspekte spiegeln sich in drei Stilmentalitäten wider, die dem Kollektionsaufbau zugrunde liegen. Sie reichen von sartorialem Anspruch über den gekonnten Mix aus zeitgemäßer Klassik und ungezwungenen Elementen bis hin zu einem urbanen, kosmopolitischen Habit. Das Ergebnis ist eine Kollektion, die sich trotz ihrer Vielschichtigkeit zu einem klaren Gesamtbild fügt und in allen Aspekten – unabhängig von Lieferterminen und thematischen Schwerpunkten – optimal miteinander kompatibel ist.

ESSENTIALS

Zeitlose Qualitäten wie Popeline, Fil-à-Fil oder Chambray bilden den Unterbau des Sortimentes und fügen sich nahtlos in das stilistische Konzept der Kollektion ein. Der Fokus liegt auf klassischen Dessinierungen und Kontrasten, die ein Spektrum von Unis über fein gezeichnete Streifenbilder bis zu Micro-Motiven und dezenten Checks abdecken.

SMART BUSINESS

Grenzen zwischen korrekt und informell werden fließend. Modern proportionierte Kentkrägen, Button-Down´s und Stehkragen-Varianten definieren den Begriff „Angezogenheit“ neu und lassen klischeehafte Vorstellungen von Business-Dresscodes hinter sich. Dieser Ansatz spiegelt sich in einem vielschichtigen Warenbild aus Unis und modernen Dessins wider. Oxfords und unterschiedliche Denim-Schattierungen werden durch farbige Twills, neue Cordqualitäten und klassische, von Anzugstoffen inspirierte Streifenbilder ergänzt. „Winter Standups“ legt den Fokus auf neue Stehkragenmodelle. Dabei werden traditionelle Dessins und Strukturen auf winterlichen Warenbildern und feinfädigen Cottons umgesetzt.

Im Fokus stehen anspruchsvolle Warenbilder mit besonderem Schwerpunkt auf klassischen Musterungen, feinen Garnen und reichen Haptiken. Diese Kernaussage wird durch den Einsatz sartorialer Ausstattungsdetails verfeinert und in eine vielschichtige, aus reduzierten Dessinierungen, Druckbildern und traditionellen Kleinmustern zusammengesetzte Materialpalette übersetzt. „Wool & Abstractions“ erweitert das Konzept um neuartige, aus klassischen Suitings abgeleitete Wollqualitäten und softe Flanelle.

STATEMENT EFFECTS

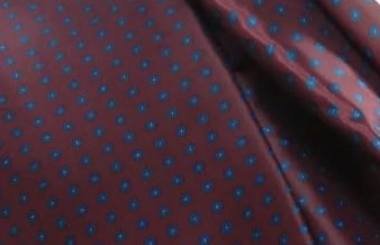

Der Themenschwerpunkt bildet einen festen Bestandteil in der Kollektionsaussage. Die Basis hierfür liefern Drucke und Dessinierungen, die ein Spektrum von großflächigen Rapporten bis zu Mikromusterungen und von grafischer Abstraktion bis zu naturalistischen Motiven abdecken. Charakteristisch für die neue Saison sind groß aufgezogene, markant kolorierte Canadian-Checks. „Velvet Spirit“ stellt bedruckte Samte und gestreifte Velvet-Optiken heraus, die den farblichen und haptischen Appeal des Warenbildes intensivieren.

DIE FARBEN

Marineblau bildet zusammen mit Weiß, Wedgwood-Blau und Bleu die Basis der neuen Saison. Dem klassischen Grundakkord werden in den drei Lieferterminen markante, modern angemischte Akzente gegenübergestellt. Der erste Liefertermin zeigt eine Kombination aus Granatrot und Piniengrün. Ein Zweiklang aus leuchtendem Umbra und Royalblau liefert einen starken Impuls und verstärkt die Aussagekraft des zweiten Liefertermins. Im dritten Liefertermin wird der Basisakkord von einem Kalt-Warm-Kontrast aus Portwein und Pazifikblau begleitet.

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

(c) Seidensticker

Textilkontor Walter Seidensticker GmbH & Co. KG