B.I.G.powers Cushion Vinyl production plant with green energy

Beaulieu International Group is investing €5 million to transition the fossil based energy supply of its Cushion Vinyl production plant in Wielsbeke, Belgium, to bio mass generated steam supply. A transition to renewable energy. To this end, B.I.G. is collaborating with A&U Energie, a company that converts non-recyclable wood waste into green energy and heat. This strategic move aligns with B.I.G.'s commitment to reach ‘net zero’ for their operations by 2030.

The transition from fossil energy to green steam and the switch to waste gas treatment without direct fossil energy brings significant benefits. First, the switch in technology will lead to 88% reduction in their Belgian Cushion Vinyl carbon footprint related to heat supply and waste gas treatment, compared to the current emissions. Second, the use of steam heating and electric energy provides improved energy efficiency. In addition, the use of steam systems is known for its safety and reliability, providing a safer and more stable heating solution for the Belgian Cushion Vinyl facility. Moreover, the switch to steam and electric energy allows for the use of green electricity in the future, if available.

In addition to transitioning to 100% green energy, Beaulieu International Group is also dedicated to advancing the circular economy. These efforts encompass various initiatives, including increasing the use of recycled and reused materials. For example, 50% of B.I.G.'s PVC floor coverings are already fully recyclable. Additionally, they are actively working to reduce the environmental impact of their solutions by 42% at the end of their life cycle, striving to minimize product emissions to nearly zero, and eliminating pollutants. Recently at the Belgian Flanders Flooring Days, Beauflor launched its Twilight collection, a cushion vinyl floor created with PVC from 100% bio and circular sources resulting in a 40% reduced CO₂ footprint compared to their conventional heterogeneous CV flooring for residential applications

Furthermore, their cushion vinyl brand Beauflor launched the ReLive concept, a specialized program designed for a circular future, ensuring the collection, sorting, and recycling of PVC flooring cutting waste. Currently, this program focuses on post-installation waste and is exclusively available in France, with the goal of expanding its reach to other EU countries.

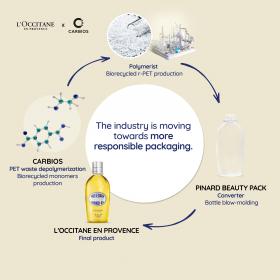

Through the establishment of strategic partnerships dedicated to finding innovative ways to repurpose waste materials previously slated for incineration, B.I.G. underscores its commitment to sustainable solutions and collaboration with like-minded organizations. 75% of B.I.G.'s post-industrial waste is now being successfully recycled.

Beaulieu International Group