SUSTAIN&INNOVATE: THE FIRST SUSTAINABILITY CONFERENCE SPECIFICALLY FOR THE FUNCTIONAL TEXTILE INDUSTRY

PERFORMANCE DAYS and SPORTSFASHION by SAZ launch their cooperation

The second day of the upcoming PERFORMANCE DAYS will be devoted fully to the issue of sustainability. In cooperation with the trade magazine SPORTSFASHION by SAZ, the fair will present the first conference for sustainability in the functional textile sector, entitled “sustain&innovate”.

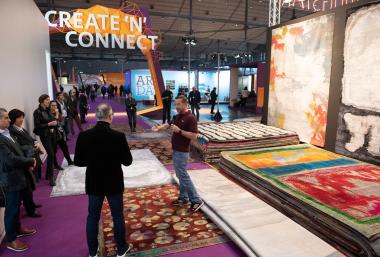

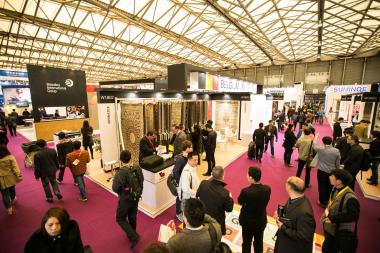

In the world of sport, as well as in fashion, functional textiles, fabrics and fibres have become indispensable. And these areas are precisely where sustainability is such an important issue, while proving just as complex at the same time. Sustainability has yet to find a real home, although sustainability events in the textile branch do exist. PERFORMANCE DAYS, in cooperation with the trade journal SPORTSFASHION by SAZ, is now taking on the challenge to specifically inform the functional textile sector, in particular about the most important and latest steps relating to sustainability. Consequently, the two key industry players are organising the first Sustainability Congress for functional textiles on November 14th in Munich, in the EXPERT TALKS Area of PERFOMANCE DAYS in Hall C1 of Munich’s fair centre.

Key speakers for the industry’s key issue

Under the title “sustain&innovate”, the November 14th will see a full day of international speakers giving talks on important and cutting-edge topics concerning sustainability, exclusively tailored to the functional textile branch.

The program is supported by the sponsors PrimaLoft, Polortec and ISKO who also exhibit at PERFORMANCE DAYS. Visitors can expect an extensive and informative program:

- Vaude managing director and sustainability specialist Antje von Dewitz will join as a keynote speaker.

- Karin Ekberg’s topic is of particular interest, where she will explain the importance of the HIGG Index for production.

- The Patagonia brand is considered a pioneer in terms of sustainability, making Patagonia’s Nicholas Allen’s presence at the conference of key importance, where specialist journalist, Charles Ross, will interview him.

- The audience can look forward to an exciting round of discussions when sustainability expert Anna Rodewald from the GreenroomVoice agency talks to international guests about the latest developments in sustainability.

- Specialist journalist Sophie Bramel will chair another interesting round of discussions entitled “Designing for Recycling” and the consideration of mono materials in the development of functional clothing.

- Martin Cieslik, Head of Sales of the renowned Hohenstein Institute, answers the important question “Why Verification Matters” in his talk.

- Sponsors of the event, such as PrimaLoft and Polartec, will also be presenting their sustainable concepts. Visitors can look forward to speakers from leading ingredient brands.

- Ulrike Arlt, editor-in-chief of SPORTSFASHION by SAZ, will moderate the program. She will also be giving a talk on the status quo of current success in relation to sustainability within the industry.

The conference will take place in the exhibition area of PERFORMANCE DAYS. The entire EXPERT TALKS Area of Hall C1 at Munich’s fair grounds will be reserved on November 14th for this innovative and unique format.

Best of all for all visitors: Not only admission to the trade fair, but also all lectures and talks at the sustain&innovate conference are free of charge! Nevertheless, it is recommended that visitors register online in advance of their arrival in order to avoid waiting times at entrances.

This absolutely unique format is completed by a special edition of SPORTSFASHION by SAZ, reporting on the conference itself and all-important sustainable issues for exhibitors, in both the German and English language. The magazine will be available at entrances on both fair days, and can be read online on the websites www.performancedays.com and www.sazsport.de, and also sent to all subscribers.

Trade fair general manager Marco Weichert is upbeat: “As a trade fair for functional fabrics and materials, we have always been a pioneer when it comes to innovation. The topic of sustainability is not only of immense importance, it will be the driving key issue for the branch in the coming years. That is why we are particularly proud that we’ve developed a unique and new format with the sustain&innovate conference, which did not exist in the branch in such a form. This allows us to reach and inform all major decision-makers internationally in relation to the manufacturing and sale of functional textiles, from fibre manufacturers to clothing brands”.

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Photo: © PERFORMANCE DAYS

Performance Days

PERFORMANCE DAYS functional fabric fair