JUMBO-Textil: "For us, leadership means team development."

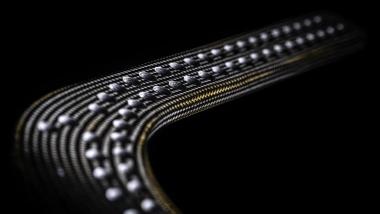

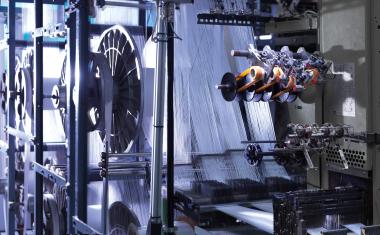

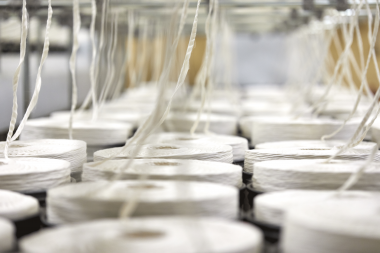

With its high-quality technical narrow textiles, JUMBO-Textil stands for high-tech - whether woven, braided or knitted. As an elastic specialist and solution partner, the company develops and produces individual innovations for customers worldwide. The 70-strong team must be as diverse and flexible as the products it designs. Textination spoke to industrial engineer Carl Mrusek about the current challenges facing family businesses. Carl Mrusek, who has been Chief Sales Officer (CSO) at Textation Group GmbH & Co. KG, to which JUMBO-Textil belongs, for almost a year now, is in charge of strategic corporate development as well as other areas of responsibility.

"In a family business, tradition is the foundation, innovation is the way forward," they say. The image of family-run companies has changed significantly in recent years - old-fashioned values and outdated business concepts have given way to a strong corporate culture, a strong sense of regional responsibility and sustainable planning. How does JUMBO-Textil combine its corporate values and traditions with a contemporary management style?

Carl Mrusek: As a family business, there is a close bond between the employees and the company and vice versa; the continuity of human relationships is important and valuable. JUMBO-Textil also has a tradition of one thing in particular: contemporary corporate management, both technically and professionally, as well as in terms of management style and values. Especially in a family business, which is often managed by the same person for decades, it is crucial to question corporate values and management style and to promote change. A company that has been operating successfully internationally for almost 115 years must be adaptable. For us, reacting quickly to changes, even anticipating them and moving forward accordingly, is at the heart of smart business practices. The specialization in elastics in the 1920s is an example of the foresighted power of change, as is the strategically important turn to technical textiles in the 1970s. A recent example is the merger with vombaur under the umbrella of the Textation Group.

The most important thing in any company is its employees. We would not be able to attract and retain them with outdated traditions and working methods. For us, the focus is not on the company management, but on joint success, and in a complex world, this is usually the result of successful cooperation and not an announcement from the boss. Leadership clearly means setting and pursuing strategic goals, but today it also means team development. Finding the best people, bringing them together and motivating them to achieve the goal.

Team spirit and vision development: How do you achieve this at JUMBO-Textil?

Carl Mrusek: As a team! JUMBO-Textil has systematically expanded its management team. In addition to the Managing Director, our CEO Andreas Kielholz, the Chief Operational Officer Patrick Kielholz, the Chief Financial Officer Ralph Cammerath, the Chief Technology Officer Dr. Sven Schöfer and myself as Chief Sales Officer work here. This shows that we are convinced of the idea of cooperation: We also work together on corporate development and strategic issues. The same applies to the individual teams - in organizational specialist teams or in interdisciplinary project teams. The tasks for which we are responsible may be different, but each is equally important.

Is that why you start the introduction of contact persons on your website with the Junior Sales Manager? And the C-level representatives are at the end?

Carl Mrusek: Yes, all JUMBO-Textil heads are the head of the company for us. All JUMBO-Textil faces represent the company. This is also reflected in the order of the contact persons on the website. Visitors should be able to quickly find the person who can help them and not find out who runs the company. That's what the legal notice is for. (laughs)

What is JUMBO-Textil's mission statement and vision for the future, and what needs to change in order to achieve this vision?

Carl Mrusek: We are currently working on the strategic direction of the Textation Group, which JUMBO-Textil GmbH & Co. KG and vombaur GmbH & Co. KG are part of. In this context, we have developed the Group's corporate vision and mission and updated our mission statement. This serves as a foundation for strategy development and is only sustainable if employees are involved in this process through surveys and workshops. I don't want to give too much away yet, but this much is already clear: strong teams, the right people in the right place, taking responsibility at all levels, sustainability as the basis for innovation - these will be the four cornerstones. You can already see from this: To achieve our vision, we cannot flip a switch. We must always remain open to change, always new - from product development to personnel recruitment. But as I said, we have a tradition of doing this.

JUMBO-Textil is not an industry specialist, but combines expertise for demanding high-tech narrow textiles. Who is in charge of challenging customer projects - do you decide in a team or rather top-down, where is the responsibility for an order placed?

Carl Mrusek: As a team, we decide which projects to implement and how to prioritize them. The corporate strategy determines the "direction of travel". In addition to the sales side, the development side of new projects also plays a decisive role. I therefore coordinate intensively with Dr. Sven Schöfer (CTO) and his team, as the focus here is on the technical development and implementation of our products. In the end, project processing is always a team effort between Sales and Development in close cooperation with Production..

Between above-standard pay, a 4-day week and the much-vaunted work-life balance in the current situation on the job market, companies are more likely to be in the position of applicants than vice versa. What are you doing to remain attractive as an employer for new colleagues? And how do you keep the enthusiasm of your skilled employees at a consistently high level?

Carl Mrusek: An important approach for us is education. Training young people and proving to them during their apprenticeship: JUMBO-Textil is your place to be. We therefore already start recruiting skilled workers through our school visits and school internships. As a state-of-the-art company, we offer an attractive salary level and a pleasant and healthy working environment.

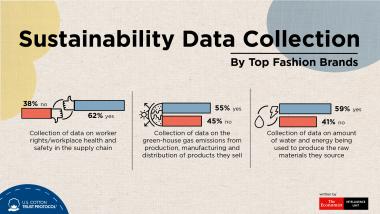

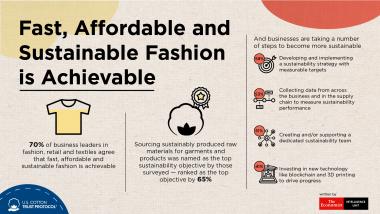

Applicants today also often want to organize their working hours and work arrangements individually and flexibly, for a variety of reasons. With modern working models and thanks to our ongoing progress in digitalization, we support them wherever possible. People also want to work for a company that they can identify with. Environmental and climate protection are just as important to our employees and applicants as social standards in our supply chain. The fact that we have set ourselves ambitious goals with our sustainability strategy and are consistently pursuing them with firmly scheduled steps - our climate-neutral energy generation is a concrete example that has already been implemented. Furthermore, we vigorously encourage our business partners to respect human and employee rights and are committed to the Code of Conduct of the German textile and fashion industry. All of this helps us to recruit staff.

What larger, more capital-intensive companies can partially make up for with financial resources, SMEs have to manage through agility and adaptability - especially in situations of crisis. To what extent are these requirements also reflected in your organizational structure and the requirements profile for employees?

Carl Mrusek: Exactly, that is the advantage that family businesses have over large corporations: We can make decisions quickly and react on a daily basis if necessary. Hierarchies are flat and coordination processes are short. An exciting suggestion doesn't have to be prepared by agencies and coordinated across several levels before it is approved by the management and can be implemented. The go-ahead can also come immediately over lunch: "Great idea, we'll do it." In a corporate group, this fails because only very few employees have the opportunity to have lunch with the management. - And we only talk about business in exceptional cases. Most of the time, the break is about family, the weather, sports and leisure plans - lunch topics, in other words. - We need responsible team players who are willing to make a change. People who work with others on an equal footing, who are committed to the company and its goals with drive and expertise and who are keen to try new things.

It now takes much more than a fruit basket and a gym to motivate current and potential employees. Working in a meaningful way and participating in a climate-friendly transformation is particularly important to many people. What does JUMBO-Textil do specifically to not just quote SDGs in a statement, but to live them in everyday company life?

Carl Mrusek: We have set ourselves a specific climate target: By 2035, our administrative and production operations at our headquarters will be climate-neutral. Realistic steps have been defined to achieve this. We have already achieved an important interim goal: at our headquarters in Sprockhövel, we only use green electricity from the sun, wind and water. We offset the unavoidable emissions for our heat generation with CO2 compensation services. We are also developing more and more products from recyclable and recycled materials. Our vehicle fleet is currently being converted to purely electric or hybrid models.

Diversification and internationalization are part of every corporate strategy these days. But what do these terms mean for the management style of a medium-sized company in Sprockhövel? Do you consciously build interdisciplinary international teams?

Carl Mrusek: We live in a hyper-diverse society. This is also reflected in our company. Our teams consist of people with different international backgrounds, without us having to actively control this. The age structure is now also very mixed. We see the different perspectives as an asset, an opportunity and a success factor. We - and that ultimately means our customers and their projects - benefit from the variety of perspectives that flow into our solutions. As with many companies in the technical textiles sector, the proportion of women in some teams is still somewhat unbalanced. However, it is fortunately increasing steadily.

Generational change and succession planning are core issues for family-run companies. How important is it for JUMBO-Textil to professionalize its management team and to what extent is the company open to external specialists and managers?

Carl Mrusek: A company that closes its doors to external specialists and managers is also closing a door to success. That would be foolish. At JUMBO-Textil, we try to combine and balance the close ties, personal continuity and flexibility of a family-run company, the passion and innovative spirit of a start-up and the solidity and financial strength of a group. With Patrick Kielholz as COO, the next generation of the family is represented at management level, as is the external view and the diversity of perspectives provided by the other new members at C-level. The Textation Group, which also includes Patrick Kielholz's brother Kevin Kielholz, supports the company and enables it to think and act bigger than medium-sized family businesses often do. JUMBO-Textil is an elastic specialist. And what distinguishes our product also distinguishes us as an organization. We span the advantages of a family business as well as those of a start-up and a group. If I may use the image of elasticity here and not stretch it too far. (laughs)

Textation Jumbo-Textil Jumbo strategy narrow textiles Carl Mrusek Technical Textiles INTERVIEW

Textination