Simian Chooses Kornit Atlas for Scaling of Direct-to-Garment Apparel Decoration

Netherlands-based operation expands on-demand garment decoration capabilities

Kornit Digital (Nasdaq: KRNT), a worldwide market leader in digital textile printing technology, announces Netherlands-based Simian, an online total print provider to more than half a million businesses and end-consumers, is implementing the Kornit Atlas digital direct-to-garment (DTG) system to increase its capacity for delivering sustainable, retail-ready decorated apparel on demand. Simian is the parent company of online print providing sites Reclameland, Drukland, and Flyerzone.

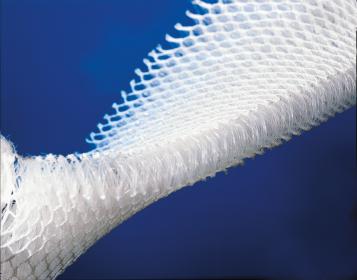

Having established itself as a total print solutions provider for signage, banners, posters, flags, and other digitally printed textiles, Simian first entered the decorated apparel market by implementing two entry-level, single-pallet DTG systems. Kornit Atlas, which can imprint more than a thousand garments per day with a single operator, will enable them to increase capacity to accommodate ongoing growth in this line of business.

Offering lower total cost of ownership than other DTG systems, Atlas meets the retail quality, wash and light fastness, and sustainability standards of the world’s largest apparel brands. Simian will use the system for nontoxic decoration of baby apparel and accessories, in addition to t-shirts, polos, sweaters, vests, and tote bags.

PR4U