INDIA'S TEXTILE AND CLOTHING INDUSTRY STRONGLY SUPPORTED

- Textile companies comparatively broadly placed

- Garment sector scores too little internationally

New Delhi (GTAI) - India is one of the world's largest manufacturers of textiles. Cotton fabrics and home textiles are among the export hits. The clothing industry plays a comparatively small role and threatens to fall behind in competition. Both areas are required to produce higher qualities and more sustainable. The Ministry of Textiles supports the fragmented industry. Foreign suppliers and buyers can explore the market at trade fairs.

The Indian textile and clothing industry is of an overall economic importance. It accounts for 14% of the total industrial production and employs directly 51 million people. Additional further 68 million people in households and micro enterprises are working for the industrial companies. Because the national economy as a whole needs to create about 12 million additional jobs per year, the government has chosen the textile industry as an employment motor. India, in contrast to the textile giant PRC, has high advantages with its labor cost.

The availability of natural materials such as cotton, jute and silk is a further advantage of the textile industry, which can look back on a long tradition of processing. India is now the world's largest producer of cotton. In the cultivation year 2016/17 year (4.1 - 31.3) estimated 5.9 million tons are expected to be harvested.

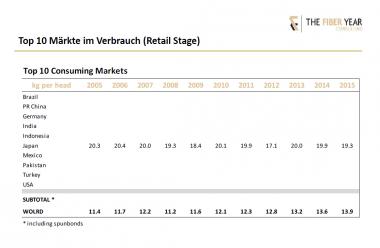

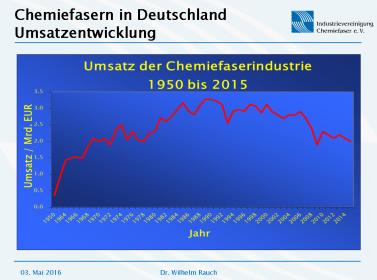

The cotton will be processed into yarns and fabrics. For the production of yarns, 61 million spindles (measured in spindle equivalents) are available. In 2015/16, they spun about 5.7 million t of yarn, of which 4.1 million t are made out of cotton fibers. The production of cotton cloths was about 38 billion sqm., mainly produced in decentralized weaving mills with simple mechanical looms. The global trend in clothing, however, goes to artificial fibers. In order to protect their domestic production the Ministry of Finance levies tariffs.

Textile industry with its own ministry and many promotional programs

The Ministry of Textiles subsidizes the sector through several programs, which support the technical modernization, the construction of industrial parks, qualification, training and marketing. Garment factories may even be reimbursed for duties and fees paid. For this purpose the budget of the Ministry of Textiles was once again significantly increased in the financial year 2017/18.

The textile and clothing industry does not only want to score on the domestic market, it also wants to play a bigger international role. In a five-year plan, the Ministry of Textiles had targeted an expansion of exports to USD 64 billion by 2016/17. This target has not yet been achieved, in 215/16 the exports of textiles and clothing amounted to USD 37.6 billion. The exports of textiles even shrank against the year before.

| 2014/15 | 2015/16 | |

|---|---|---|

| Export of textiles in USD Billion | 21.7 | 20.6 |

| Imports of textiles in USD Billion | 5.5 | 5.4 |

| Export of clothing in USD Billion | 16.8 | 17.0 |

| Imports of clothing in USD Billion | 0.5 | 0.6 |

| Change in the production of textiles (in %) | 3.7 | 2.2 |

| Change in the production of clothing (in %) | 0.2 | 14.7 |

Sources: Ministry of Textiles, Ministry of Statistics and Programme Implementation

The local garment industry has good chances of development on a large and growing domestic market. According to industry estimates the retail sector sold clothing worth approximately USD 45 billion in 2016. Experts say the world's fifth-largest market is expected to grow well above 10% in the medium term. The backlog of the 1.3 billion inhabitants is not yet covered. The trade imports international branded goods mainly from China and Bangladesh. Standard articles and custom-made products are sewn by the local industry.

Garment sector with opportunities and problems

Cheap wages are a location advantage. They vary however very different within the subcontinent. The statutory minimum wage regulations differ between the 29 federal states. In addition the person's age, the company membership and abilities are used to calculate the minimum wage.

Due to the increasing production costs in China, labor-intensive manufacturing is moving to more favorable locations. Not only labor costs play a major role here. The complex labor law strongly restricts the efficiency of labor markets in India. Investors consider the labor law, logistics and the structure of supply chains as to be difficult. The World Bank found in its study "Stitches to Riches" in 2016 (see https://www.openknowledge.worldbank.org/handle/10986) that Bangladesh, Indonesia, Cambodia and Vietnam, surpass the competitor India in the points quality, delivery times, reliability and sustainable social responsibility.

India is also missing free trade agreements (FTAs) which facilitate access to international markets and regulate them reliably. The European Union and India have been negotiating as an example a comprehensive FTA for over 10 years with longer interruptions.

Fragmented sector structure with international Champions

Information on the number of companies, their size classes and investment volumes are not available. Smaller textile companies and retailers are partially not registered and do not pay taxes. Medium-sized companies are very flexible, but they need to mechanize, automate and upgrade technically in order to survive.

Larger companies look back on their long-standing tradition and have developed into internationally networked corporations. According to the Indian financial service Moneycontrol, the three largest corporations in the clothing industry are: KPR Mills (last net sales circa USD 300 million), Page Industries (USD 270 million) and Gokaldas Exports (USD 170 million); In the textile sector in general: Bombay Rayon (some USD 640 million), Sutlej Textiles (USD 350 million), SEL Manufacturing (USD 300 million), Mandhana Industries (USD 250 million); in the knitting sector: Nahar Industrial Enterprises (USD 270 million), Rupa (USD 160 million); Cotton spinning: Vardhman Textiles (USD 860 million), Trident (USD 560 million), Indo Count (USD 310 million); Spinning of synthetic fibers: RSWM (USD 450 million), Indorama (USD 390 million), Sangam (USD 230 million); Weaving and other processes: Alok Industries (USD 1.8 billion), Welspun (USD x750 million), Garden Silk (USD 370 million); Other areas: Arvind (USD 830 million), Nahar Spinning (USD 310 million), JBF Industries (USD 550 million), Bombay Dyeing (USD 280 million).

Foreign textile companies invest and explore

The government is promoting the "Make in India" campaign in the textile sector for foreign direct investments. Company foundations are for 100% in foreign hands (see http://www.makeinindia.com/sector/textiles-and-garments). The sector attracted USD 2.4 billion from 2000 to 2016 in FDI.

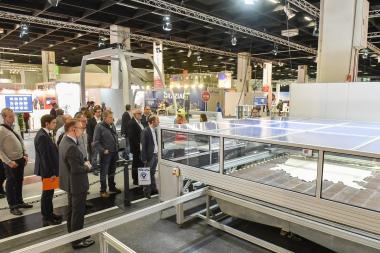

Foreign companies can explore the markets at various trade fairs. The textile ministry wants to expand the “Textiles India”, which took place in Gandhinagar (Gujarat) in June 2017, to a mega-event (https://www.textilesindia2017.com). The international garment industry also met at the same time at the „India International Garment Fair" (http://www.indiaapparelfair.com).

The "National Garment Fair" will take place from July 10th to 12th in Mumbai (http://cmai.fingoh.com/event/65th-national-garment-fair-1/Registration). And Messe Frankfurt is organizing "Techtextil India" from September 13th to 15th in Mumbai. Here German exhibitors can participate in a community stand (http://www.auma.de/de/messedatenbank/seiten/moesetailseite.aspx?tf=135499).

| Name | Internet address | Remarks |

|---|---|---|

| Germany Trade & Invest | http://www.gtai.de/Indien | Foreign trade information for the German export economy |

| AHK Indien | http://www.indien.ahk.de | Starting point for German companies |

| Ministry of Textiles | http://www.texmin.nic.in | Ministry |

| Office of Textile Commissioner | http://www.txcindia.gov.in | Authority |

| Confederation of Indian Textile Industry | http://www.citiindia.com | Textile confederation |

| Textile Association India | http://www.textileassociationindia.org | Textile industry association |

| The Clothing Manufacturers of India | http://www.cmai.in | Clothing industry association |