EU Project: System Circularity & Innovative Recycling of Textiles

SCIRT stands for System Circularity & Innovative Recycling of Textiles. Coordinated by VITO, an independent Flemish research organisation in the cleantech and sustainable development sector, SCIRT is a three year EU-funded project from the Horizon 2020 Programme.

It aims to demonstrate a complete textile-to-textile recycling system for discarded clothing—or post-consumer textiles—involving stakeholders throughout the value chain and focusing on the recycling of natural fibres, synthetic fibres and fibre blends. To reach this goal, the project has set four main objectives.

- Deliver a closed-loop recycling solution for discarded textiles.

- Stimulate and encourage conscious design as well as production practices.

- Create new business opportunities by boosting textile value chain activity.

- Raise awareness of the environmental and social impacts of buying clothes.

Gathering 18 partners from five countries, the SCIRT project held its virtual kick-off meeting in mid-2021 to begin tackling the issue of clothing waste and recyclability, one of the biggest challenges faced in the fashion industry today.

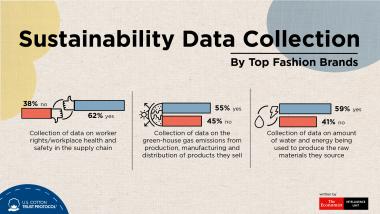

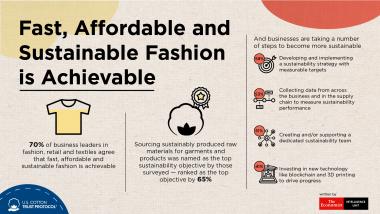

As clothing brands are setting ambitious targets and making promises to incorporate recycled fibres in their products, discarded textiles are piling up in abundance around the globe. Though it would seem that the stars of supply and demand have aligned for this part of the circular economy, the truth is that less than 1% of textile waste is recycled into new textile fibres, according to an Ellen MacArthur Foundation report published in 2017. This miniscule percentage is indicative of a greater problem-achieving circularity in the fashion industry is not just a question of supply and demand, but of the connection between the two. There is a lack of knowledge surrounding the technological, economic and environmental feasibility of recycling fibre mixtures, and a need to align the quality and cost of recycling processes with the demands of textile companies and fashion brands.

SCIRT will develop solutions to support systemic innovation towards a more circular fashion system and bridge this supply-demand gap. To address the demand side of the equation, SCIRT will demonstrate a complete textile-to-textile recycling system for discarded clothing, otherwise known as post-consumer textiles, involving stakeholders throughout the value chain and focusing on the recycling of natural and synthetic fibres, as well as fibre blends. With the support of technical partners and research institutes, clothing brands Decathlon, Petit Bateau, Bel & Bo, HNST and Xandres, will develop, prototype and produce six different representative types of apparel using post-consumer recycled fibres. These include formal and casual wear, sportswear, underwear and uniforms. Through this endeavour, SCIRT will prioritise quality and cost-effectiveness in order to ensure market confidence and encourage the broad uptake of post-consumer recycled fibres.

From a non-technological perspective, SCIRT will develop supporting policy measures and tools to facilitate the transition towards a circular system for apparel. This includes a framework for an eco-modulated Extended Producer Responsibility (EPR) system and a True Cost Model to quantify circularity and increase value chain transparency. Special attention will also be given to the consumer perspective. To this end, Citizen Labs engaging consumers in various European locations, as well as a wider online engagement platform, will be developed to engage citizens throughout the project in order to understand the perceptions, motivations and emotions shaping their behaviour regarding the purchase, use, and disposal of textiles.

Over the next three years, SCIRT project partners will work to overcome current technological, economic, socio-economic and regulatory barriers faced in textiles recycling to achieve a real, lasting circular fashion economy.

2021:

The SCIRT project kicks off and partners identify the current state-of-the-art in apparel design, production and recycling, challenges and market trends, and stakeholder needs.

2022:

Designing and testing a fibre-to-fibre system by producing recycled yarns and filaments, free from harmful substances.

2023:

Formal wear, casual wear, sportswear, underwear and uniforms will be designed and produced using the optimized yarns developed.

Partners

- Fashion companies: Bel&Bo, HNST, Decathlon, Xandres, Petit Bateau

- Research organisations: VITO, CETI, Prospex Institute

- Universities: BOKU, TU Wien, ESTIA

- Industry players: Altex, AVS Spinning - A European Spinning Group (ESG) Company, Valvan

- SMEs: Circular.fashion, FFact

- Non-profit organisations: Flanders DC, IID-SII

ALTEX

ALTEX is a textile recycling company based in Germany that employs state-of-the-art machinery to recycle textile waste into new high-quality products. Its products include teared fibres, natural fibres, synthetic fibres and fibre blends among others.

Bel & Bo

Bel&Bo is a family-owned Belgian business with about 95 retail stores located throughout Belgium. Its mission is to offer colourful, fashionable and sustainably produced clothing for men, women and children at an affordable price.

CETI

The European Center for Innovative Textiles (CETI) is a non-profit organisation dedicated to conceiving, experimenting with and prototyping innovative textile materials and products through both private and collaborative R&D projects.

circular.fashion

circular.fashion offers software for circular design, intelligent textile sorting and closed-loop recycling, including the Circular Design Software and the circularity.ID®, as well as training and hands-on support to fashion brands in their transitions.

Decathlon

With over 315 stores in France, and 1,511 around the world, Decathlon has been innovating since 1976 to become the main player for athletic people. It has been engaged in reducing its environmental impact through a number of actions.

ESG

The European Spinning Group (ESG) is a textile group based in Belgium that offers a range of yarns produced with a highly technological open-end spinning mill for different applications, such as for interiors, fashion and technical textiles.

ESTIA

ESTIA is a French institute that has provided education and training in the areas of industrial technologies for 20 years. Since 2017, ESTIA has had a program focused on new materials and disruptive process in the fashion and textile industry.

FFACT

FFact is a unique group of management consultants that facilitates the implementation of sustainability from a business perspective, and translates facts into useful management information. FFact is based in the Netherlands and Belgium.

Flanders DC

The Flanders District of Creativity, a non-profit organisation based in Belgium, informs, coaches, promotes and inspires creative entrepreneurs in various sectors, including the fashion industry, who want to build or grow their business.

HNST

HNST is a Belgian circular denim brand that recovers post-consumer denim and recycles it into new fabric in the EU, creating durable and 100% recyclable jeans that use 82% less water and emit 76% less carbon dioxide than conventional jeans.

Petit Bateau

Petit Bateau is a French apparel brand that specialises in knit products. As a vertical company, Petit Bateau carries out its own knitting, dyeing, making up and store management with the support of its 3,000 employees.

Prospex Institute

The Prospex Institute aims to promote the participation of citizens and stakeholders in socially relevant decision-making dialogue and development by engaging with theorists and practitioners both in Belgium and abroad.

IID-SII

The Sustainable Innovation Institute is a French non-profit association based in Paris. Initiated by LGI, a French SME, the purpose of IID-SII is to act as a think and do tank on sustainable innovation to support the adoption of novel solutions.

TU Wien

TU Wien is an open academic institution where research, teaching and learning have taken place under the motto “Technology for people” for the past 200 years. One of its key areas of research is on recycling technology and fibre innovation.

BOKU

Research at the Institute for Environmental Biotechnology of BOKU based in Vienna, Austria focus on the exploitation of enzymes as powerful biocatalysts for biomaterials processing within recycling applications.

Valvan

Valvan Baling Systems has 30 years of experience in designing and constructing custom-made machinery, specialising in Baling Machines and Sorting Facilities for fibre producers, collectors, sorters and recyclers of textiles.

VITO

VITO, a leading independent European research and technology organisation in the cleantech and sustainable development sectors, aims to accelerate the transition towards a sustainable society by developing sustainable technologies.

Xandres

Xandres is a brand inspired by and for women. It is rooted in a highly respected tradition of fashion, driven by quality and created for the life women lead today. Xandres offers innovative designs with respect for luxury and the environment.

SCIRT Recycling circularity ALTEX Bel & Bo CETI circular.fashion Decathlon ESG ESTIA FFACT Flanders DC HNST Petit Bateau Prospex Institute IID-SII TU Wien BOKU Valvan VITO Xandres

Textination / SCIRT