Sustainable Athletic Wear Made from Bio-Based Polyethylene

Conventional sports textiles made from petroleum-based synthetic fibres are to be replaced in the future by sustainable, bio-based, cooling textiles. Polyethylene, previously used mainly in the packaging industry, is thus qualified for use in textiles and, as a bio-based drop-in solution, offers a cost-effective, sustainable alternative for the future.

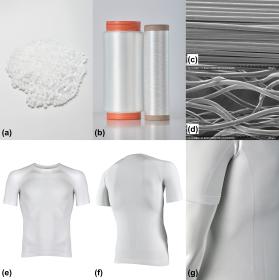

TECNARO (Ilsfeld/Germany), BB Engineering (Remscheid/Germany), FALKE (Schmallenberg/Germany) and the Institut für Textiltechnik (ITA) of RWTH Aachen University have developed textiles from bio-based polyethylene (bioPE) in the bioPEtex project of the BIOTEXFUTURE Innovation Space.

TECNARO develops the bio-based PE compounds and handles their dyeing. ITA is concentrating on the process development for melt spinning (partially-oriented yarn, POY) and false-twist texturing (draw-textured yarn, DTY) of the bioPE yarns. BB Engineering implements the false-twist texturing on an industrial scale, and FALKE is developing the final T-shirt, which will be treated with a bio-based finish for improved elasticity.

The successful creation of a first T-shirt from the yarns developed in this project underscores their promising characteristics. This represents a key milestone and forms the basis for investigating potential market readiness in subsequent phases. Above all, the white BioPE T-shirt impresses with its pleasantly cool and soft touch. However, additional development, characterisation, and optimisation steps are necessary to make a market introduction possible.

sportswear and athleisure Sportswear synthetic fibers and yarns polyethylene biobased

ITA – Institut für Textiltechnik of RWTH Aachen University