DigiPEP: Components designed according to the load path

Abstract

Developing components made of fibre-reinforced plastics, is often performed with the focus on the lightweight construction aspect. For this purpose, the occurring load cases are determined on the basis of the boundary conditions and forces. Afterwards, the component is designed accordingly. If this intention is taken even further, the method is usually assigned to the field of Tailored Textiles. Tailored Textiles are, as the term suggests, textiles that are manufactured to suit the application. This also includes the Tailored Fibre Placement (TFP) process. In this process, rovings can be laid down and stitched in a variable axial direction. With this type of placement, embroidery patterns can be created according to the load cases that occur in the moulded component. The process is thus extremely low in waste and can be used for local reinforcement in the form of inserts or as an entire component with an enormous lightweight construction approach. In combination with low acquisition and process costs, the process offers great potential, especially for SMEs.

Report

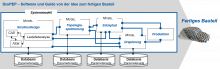

During the product engineering process (PEP) of fibre composite components made from TFP preforms, a large number of iterations is necessary to ensure the desired properties in the finished component. Especially the interaction of the different process steps from roving deposition, draping to infusion and the occurring interactions complicate the component design. In order to link the required design processes and thus reduce the number of iterations as much as possible, the Model Based Systems Engineering (MBSE) approach is used in the DigiPEP project (see Fig. 1). This approach makes it possible to integrate the different models and assign tasks to individual responsible persons. The overall aim is to create a model with a user interface that requires only the most important boundary conditions and decisions from the responsible person. Models for structural analysis, stick path design, topology optimisation, draping and failure analysis of the finished component are to be integrated into the model. Furthermore, a cost estimation as well as a form of life cycle analysis shall be enabled. The generated model will be validated by the design of a demonstrator component. This demonstrator component can be located in the field of future transport and production.

The two-year project is funded by the Federal Ministry of Economics and Climate Protection (BMWK) as part of the Lightweight Construction Technology Transfer Programme under funding number 03LB3063A. The following partners are involved in the project: EDAG Group, Digel Sticktech GmbH & Co. KG, ModuleWorks GmbH, Ph-MECHANIK GmbH & Co. KG, adesso SE.

Contact: rebecca.emmerich@ita.rwth-aachen.de

ITA Institut für Textiltechnik an der RWTH Aachen University, Otto-Blumenthal-Strasse 1, 52074 Aachen, Germany

More entries from ITA Institut für Textiltechnik der RWTH Aachen University