Rieter auf der ITMA Asia + CITME 2021 im Juni 2021

Ensuring Competitiveness Through Technology

Seit Beginn der Pandemie hat Rieter seinen Einsatz in Forschung und Entwicklung verdoppelt, um die Entwicklung intelligenter und automatisierter Maschinen und Systeme voranzutreiben, damit Kunden Garn profitabler, effizienter und nachhaltiger produzieren können. Dadurch können Spinnereibetreiber flexibel auf sich schnell verändernde Märkte reagieren.

- Ringspinnen mit G 38 und ROBOspin setzt neue Maßstäbe bei der Automatisierung

- COMPACTapron ermöglicht eine neue Dimension der Garnfestigkeit

- ESSENTIAL: neue Funktionen mit intelligenteren Einblicken für bessere Entscheidungen

- ROBOdoff automatisiert das Doffen und spart so Zeit und Geld

- Neue SSM-Spulmaschine NEO-YW effizient und nachhaltig

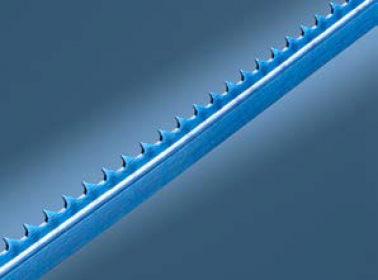

- Längere Lebensdauer und höhere Qualität dank neuer Trommelgarnitur und Deckel von Graf

Rieter Management AG