Heberlein at ITMA Asia + CITME 2025: Jets developed for filament perfection

Heberlein, a leading supplier of air interlacing and air texturing jets, aims to impress visitors at ITMA Asia + CITME 2025. Novel solutions will be presented, which will allow filament yarn producers to achieve special quality specifications and process optimization. These latest developments combine the most sophisticated technology with user convenience and savings potential.

Data in the ‘Fibre Year 2024’ report confirms that synthetic fibres continue to outpace natural fibres, growing by 8.4% against 2.7% – and this upward trend is expected to continue. Man-made fibre hubs such as China (+8.8%) and India (+7.7%), and also Vietnam (+8.9%) show significant growth. Looking at the development of different synthetic materials, polyamide stands out, with a notable increase of 4.1%, underscoring its promising future. In the forefront of these developments are Swiss-made key components from Heberlein, delivering cutting-edge technology that powers quality and efficiency in polyamide yarn production.

DTY jets for demanding spinners and yarns

Launched at ITMA 2023, the Heberlein APe series was expanded with new types of jets. The two additional jets are particularly suitable for polyamide with fine titers.

This DTY jet series sets new standards in yarn processing. Developed for the efficient processing of fine polyamide yarns with a particularly high number of knots (FP/m), the successful APe series is renowned for its unique performance of more than 200 knots per metre. Despite its outstanding performance, it is the smallest jet in its class – fitting anywhere and best suited wherever air savings and optimized production efficiency are required.

The APe series is also attracting interest from market players striving for sustainable production through various measures. Its capability for equal knot performance with reduced energy consumption delivers sustainability without compromise.

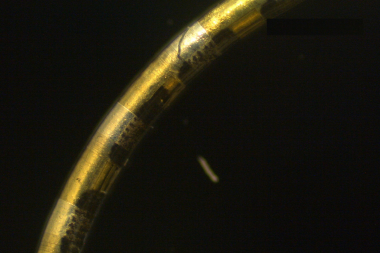

Air splicing: maximum control and minimum effort

Yarn splicers produce a tear-resistant, homogeneous splice of material without knots. All they need is compressed air. Heberlein's AirSplicers produce first-class splices for a wide range of applications for technical fibers where extreme strength characteristics are needed.

The new AirSplicer-Basix was designed for technical yarns – including aramid, glass, and carbon. The splicer offers maximum control and user-friendly operation.

The sophisticated blow chamber design makes it easy to insert, splice and remove the yarn without any additional manual steps or the need for the user to activate further mechanisms.

The design of the AirSplicer-Basix is reduced to the essentials. Still, it performs convincingly and offers flexibility as one or more connection points can be created, depending on the material used and the desired splice strength.

Heberlein Technology AG