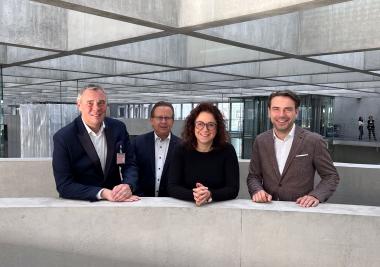

Freudenberg Performance Materials: Dr. Andreas Raps new CEO and Marco Altherr new CFO

New appointments to the Management Board of Freudenberg Performance Materials come into effect on January 1, 2024: Dr. Andreas Raps succeeds Dr. Frank Heislitz as Chief Executive Officer (CEO), and Marco Altherr takes over from Thomas Herr as Chief Financial Officer (CFO). From January 1, 2024, the Management Board of Freudenberg Performance Materials will therefore consist of: Dr. Andreas Raps (CEO), Marco Altherr (CFO) and John McNabb (CTO). McNabb has been CTO since 2018. Dr. Frank Heislitz and Thomas Herr become members of the Freudenberg Group Board of Management on January 1, 2024.

Dr. Andreas Raps has been a member of the Freudenberg SE Executive Council since 2020 and CEO of EagleBurgmann, a joint venture between the Japanese EKK Group and the Freudenberg Group, since 2016. He previously held several executive management positions at Freudenberg Sealing Technologies from 2004, most recently as CEO of the global Special Sealing Division with 17 manufacturing sites worldwide. Before joining the Freudenberg Group, Raps worked for various management consulting companies in Boston, USA, Munich, Germany, and Zurich, Switzerland. He holds an MBA from the University of Passau. Alongside his job as a consultant, he obtained a PhD with a thesis on strategy implementation in Business Administration.

Marco Altherr has been CFO of Vibracoustic SE, a Freudenberg Group company, since 2020. He held various senior management positions at Freudenberg & Co. KG, the technology group’s holding company, from 2015 to 2020, most recently as Head of Corporate Controlling and Accounting. Prior to joining Freudenberg, he served in several management roles at Manroland AG, Heidelberger Druckmaschinen, Boehringer Ingelheim and Arthur Andersen. He holds a degree in business administration specializing in controlling and financing from Lahr University.

Freudenberg Performance Materials