Rieter: First Half of 2019 Characterized by Low Demand in the New Machinery Business

- Order intake in the first• Order intake in the first half of 2019 amounted to CHF 378.3 million, 26% below the previous year period

- At CHF 416.1 million, sales were 19% down on the previous year period

- EBIT of CHF -1.2 million and net profit of CHF -3.8 million

- Implementation of cost-cutting measures proceeding according to plan

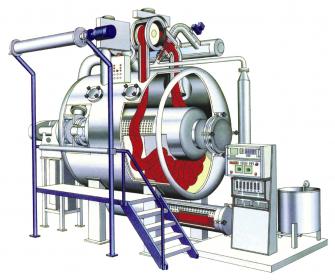

- Innovations successfully launched at ITMA 2019 in Barcelona

- Major order from Egypt signed – worth around CHF 180 million

- Completion of real estate sale in Ingolstadt (Germany) expected in the third quarter 2019

- Outlook unchanged compared to spring 2019

In the first half of 2019, Rieter posted an order intake of CHF 378.3 million (first half year 2018: CHF 511.8 million). This represents a decline of around 26% compared to the previous year period. As already reported, the main reason was low demand in the new machinery business (Business Group Machines & Systems: -34%). Rieter understands that market share remained unchanged at the previous year’s level of around 30%. Order backlog as at June 30, 2019 was CHF 295 million (December 31, 2018: CHF 325 million).

Rieter Holding Ltd.

Rieter Management AG