Reju announces French site for regeneration hub

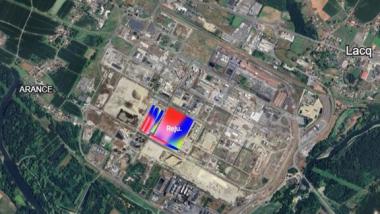

Reju, the textile-to-textile regeneration company based in France, announces the site selection for an industrial sized Regeneration Hub, in Lacq, in the Pyrénées-Atlantiques, on the Induslacq platform. Reju, a Technip Energies owned company, is deepening its roots in France through the development of this new Regeneration Hub.

Every year, 121 million tonnes of textiles are discarded, yet only 1% are recycled into new garments. The vast majority end up in landfills or are incinerated, creating a severe environmental challenge for the world. Reju is tackling this global issue by developing solutions to regenerate textile waste into new materials.

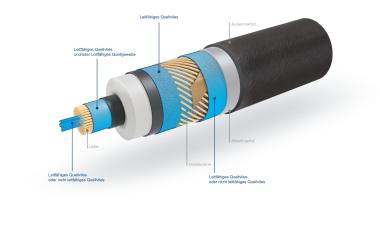

This Regeneration Hub will strengthen France’s leadership in circular, low carbon industrial innovation. Backed by Technip Energies’ global engineering expertise, Reju will bring cutting edge textile to textile regeneration technology to French industry. The plant will utilize Reju’s proprietary depolymerization technology to take post-consumer textiles from national waste streams as feedstock and to transform them into rBHET, a regenerated raw material for making new polyester from textile waste, that will then be repolymerized into Reju PET.

The project is subject to final investment decision by the board of Technip Energies, the parent company of Reju.

This project will help structure a new local industry, contributing to decarbonization. It would generate 80 direct jobs and more than 300 indirect jobs. “This French Regeneration Hub builds on our strategy to industrialize a circular post-consumer textile-to-textile model,” said Patrik Frisk, CEO of Reju. “By leveraging France’s ambitious circular-economy agenda and advancing our technology to new markets, we are reinforcing our mission to transform textile waste into valuable, circular resources.”

Through its French Hub, Reju aims to build a scalable circular infrastructure in France and Europe, enabling textile-to-textile traceability and closing the loop on fiber use. The project aligns with Reju’s established operations, including Regeneration Hub Zero in Frankfurt, the announced site selection in Chemelot, Sittard-Geleen the Netherlands and the recently announced United States Hub to be located in Eastman Business Park, in Rochester, New York.

The Regeneration Hub will be located on the Induslacq platform, owned by TotalEnergies.

Owned by Technip Energies, Reju utilizes proprietary technology developed in conjunction with IBM Research to recover, regenerate and recirculate textile waste, starting with polyester.

Reju actively participates in the work of several bodies and organizations such as ReHubs, Petcore and Evolen. This will create a circular ecosystem, developing a textile-to-textile sector in France in line with European requirements and based on traceability.

Reju