First sustainable biking uniform

- Launched by SCOTT Sports Racing Team with Sitip, Rosti and ROICA™ by Asahi Kasei

The collection was designed starting from the needs of the athletes with the aim to offer them the best solution in terms of style and ergonomics, high performance, easy maintenance and perfect fit being also sustainable.

Ispo 2020 saw the celebration of the partnership started last year between Scott Racing Team, Rosti, Sitip and ROICA™ by Asahi Kasei for the supply of the team riders’ uniforms. Rosti worked on style and packaging, Sitip on technical fabrics ‘BE-HOT - Heat Generating fabrics’, while ROICA™ provided its premium stretch ingredient. The collaboration carries an interesting news: uniforms are not just highly performing but also, and above all, sustainable.

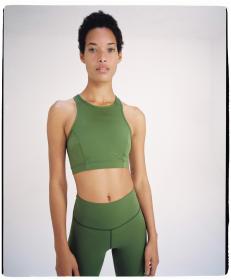

Sitip created the Native fabric entirely made with recycled yarns and featuring the premium high performing ROICA™ EF elastomer. The yarn is certified GRS - Global Recycled Standard certification (and also provides special dyeability) with Rosti’s design and high care garment manufacturing.

The main rider of Scott Racing Team Italy, the young and award-winning champion Juri Ragnoli, the “end user” of the uniforms, explaines the requirements that garments should possess in order to meet the sporting challenges that await athletes: breathability, comfort on the skin, performance, durability of the shape and maintenance of the characteristics throughout the course of use of the garment. When asked about the arrival of a new sustainable uniform, the champion said that “it’s right and important to take this direction, which perfectly meets the team’s values, as love for nature and respect for the environment. It will be nice to wear something that follows exactly what you believe in”.

GB Network Marketing Communications Srl