Domotex 2020: Manmade Fibers shows BCF S8 with new CPC-T

Market leader Oerlikon Neumag has its finger firmly on the pulse of their customers with the new Color Pop Compacting unit (CPC-T) for the BCF S8 carpet yarn plant, which is now available for the Polyamide 6 process. The new solution, which was on show from 10-13 January 2020 at the Domotex 2020 in Hannover, attracted great interest from many trade visitors.

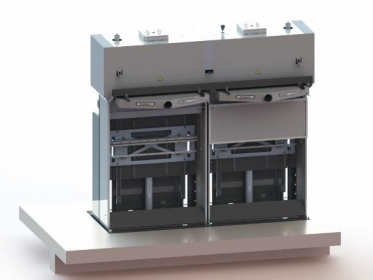

Following the trend for multicolored carpets, BCF S8 sets new standards in regards to color separation. The plant, launched as a tricolor solution at last year’s ITMA in Barcelona, makes anything possible – from mélange to strongly separated. It promises carpet yarn producers even more flexible color mixing variants for product differentiation. The core component in this process, the Color Pop Compacting unit (CPC-T), offers more than 200,000 different color shades from three colors. The innovation, which has been filed for patent, is available for polypropylene and polyester polymers as well as for the polyamide 6 process.

Polyester, recycling polyester and fine titers are on trend

During numerous conversations with customers, Martin Rademacher, Head of Sales Oerlikon Neumag, observed a noticeable trend for polyester in the carpet industry even outside the USA. Sustainable solutions are equally sought after: “Our customers increasingly demand plants that can process recycled polyester,” explains Martin Rademacher.

The Manmade Fibers segment presented an additional solution by Oerlikon Barmag for polyester applications that need fine single filament titers from 0.5 dpf and high filament counts: Puffy, soft polyester filament yarns with BCF-similiar properties are produced on the basis of a POY and texturing process. Core components of the processes are the POY take-up unit WINGS HD as well as the new texturing machine eAFK Big-V.