SHIMA SEIKI at IGATEX Pakistan 2024

Computerized flat knitting technologist SHIMA SEIKI MFG., LTD. of Wakayama, Japan will exhibit at the upcoming International Exhibition for Garment, Textile Machinery and Accessories (IGATEX Pakistan 2024) exhibition in Lahore, Pakistan.

On display will be SHIMA SEIKI’s N.SSR®072 14G computerized flat knitting machine and SDS®-ONE APEX4 3D design system.

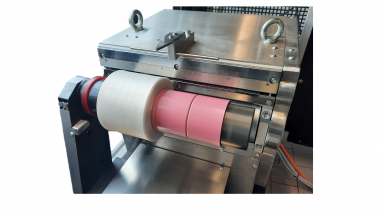

Shown for the first time in Pakistan, SHIMA SEIKI’s new N.SSR®072 computerized jacquard collar machine can produce shaped collars efficiently based on computer-generated designs. N.SSR®072 is based on the workhorse N.SSR®112 garment shaping machine, and offers similar leading technology in an economical yet reliable package.

Design is demonstrated on SHIMA SEIKI's SDS®-ONE APEX4 design system. At the core of the company’s "Total Fashion System" concept, it provides support throughout the supply chain, integrating production into one smooth and efficient workflow from yarn development, product planning and design, to machine programming, production and even sales promotion. Especially effective is the way SDS®-ONE APEX4 improves on the product planning and design evaluation process by replacing physical samples with digital prototypes. Based on photo-realistic simulations, these virtual samples minimize the need for actual sample-making, realizing significant savings in time, cost and material.

SHIMA SEIKI MFG., LTD.