ILUNA Group presents new naturally-dyed Yoga Capsule Collection

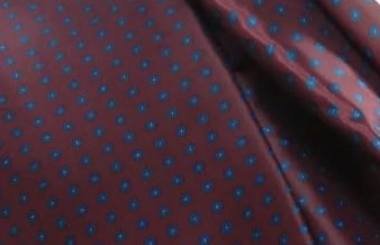

Iluna is bringing to the Parisian leading trade show for lingerie Interfilière its responsible offer and a unique Yoga capsule collection. The Yoga Capsule collection is characterized by the inclusion of responsible premium ingredients such as GRS certified Q-NOVA®, made for more than half by pre-consumption waste, and the GRS certified premium stretch yarn ROICA™ EF constructed out of more than 50% pre-consumer recycled content. Unique added value of the capsule is that it is enriched by natural based GOTS certified dyestuffs, a safe alternative to the chemical ones. A collection with a ten shades color offer strictly linked to the seasonality with high color fastness and durability respondent to the OEKO-TEX® Standard 100 certification.