Hudson-Sharp and PCMC to exhibit together at K2019

Joint booth to host demonstrations of Apollo wicketer and Meridian laser anilox cleaner

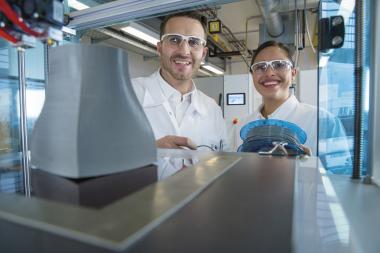

Hudson-Sharp and Paper Converting Machine Company (PCMC), both part of Barry-Wehmiller, will be showcasing equipment at K2019 (hall 3, B16), held 16 to 23 October, 2019, in Düsseldorf, Germany. Hudson-Sharp joined PCMC as of October 1, 2019, and attendees may visit the companies’ joint booth during the show to view live demonstrations of two innovative machines.

Hudson-Sharp will be demonstrating its brand-new high-speed Apollo wicketer, with quick changeover features, automation, enhanced ergonomics and user interface, and increased output speeds. The Apollo’s smart features will enable customers to reduce scrap rates and collect improvement metrics to assist in production decisions.

PCMC will be showcasing its Meridian laser anilox cleaner, which quickly deep-cleans anilox cells with a laser to remove deposited particles inside of the cells. This cleaning technology extends the life of anilox rolls and does not require any chemicals, sodium bicarbonate, polymer beads, water or detergents—making it a sustainable technology with a very low environmental impact. PCMC’s newest Meridian models include updated controls and a new internal traversing vacuum system.

Barry-Wehmiller