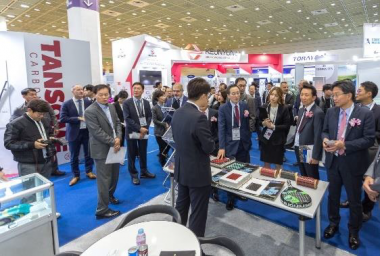

Strong exhibitor registration shaping up for Intertextile Shanghai Home Textiles – Autumn Edition

Exhibitor registration for the Autumn Edition of Intertextile Shanghai Home Textiles has been strong since applications opened in December last year. Renowned global players such as D Décor Home Fabrics (India), G.M. Syntex Pvt (India), Naturtex (Hungary) and SIC Global Textiles (Poland) are amongst those to have already confirmed their participation. Held from 24 – 26 August 2020, the fair is the largest trade platform in China for international buyers to meet potential supply partners in the second half of the year. The fair’s early bird discount will be extended until 30 March. Interested companies can register online to enjoy a 10% discount.

Discover abundant new products and design trends

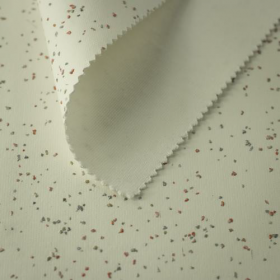

As the leading business platform for the home and contract textile industry in the Asia Pacific region, participants of Intertextile can always discover the latest innovations and trends of the textile and interior design industry. This year, the fair continues to cover the entire spectrum of home and contract textile products including:

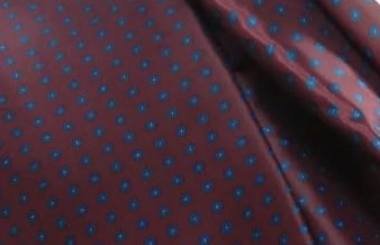

- Decorative Fabrics (Upholstery & Curtains)

- Bedding, Bath, Kitchen & Table

- Carpets & Rugs

- Sun-Protection

- Wallcoverings

- Textile Editors

- Whole Home Products

- Digital Print & Technics

- Fibres, Yarns & Chemicals

- Textile Designs

In addition, Intertextile is pleased to cooperate with the renowned international forecasting agency NellyRodi™ from France again in presenting the hottest international home furnishing trends. A trend committee led by NellyRodi and formed by top forecasters including Carlotta Montaldo, Juliette Lamarca, Shen Lei and Studio NOCC will be responsible for determining the major design trends which will be demonstrated in the three-day fair via a series of events and displays. More details about the trends will be announced soon.

Messe Frankfurt