KfW: EUR 20 million for textile workers affected by the Corona pandemic

- Rapid assistance to more than 200 000 people affected

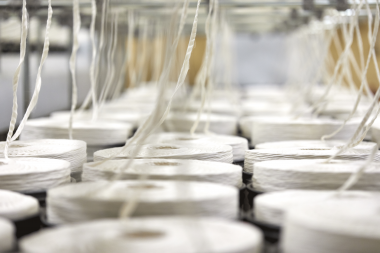

Many hundreds of thousands of textile workers in Bangladesh are at risk of sliding into poverty as a result of the outbreak of the Corona pandemic. According to EU estimates, about half of the four to five million workers in the sector have either been laid off or made redundant since spring 2020 – in some cases without social security to back them up. To mitigate the dramatic economic consequences, the EU is now redirecting its existing sector budget support to Bangladesh. From now on, around EUR 90 million is to be channelled into a new government programme to finance wage substitution benefits for workers made redundant in the textile sector - including the leather and shoe industries – or at least to provide a short-term interim solution for workers who have been dismissed. German Financial Cooperation (FC) is now increasing these EU funds by EUR 20 million.

"The textile sector," says KfW office manager Anirban Kundu, "is the backbone of the economy in Bangladesh. The export share of the textile industry alone accounts for 86% of the economy, and the total trade volume is around USD 40 billion. If it is doing badly, the whole country is doing badly."

The corona pandemic is therefore causing enormous disturbances in the sector. Many orders were cancelled and goods already produced were often not taken. "Even though the situation has eased somewhat in the meantime," Kundu continues, "things remain critical - not least because of increased price pressure or because orders have not reached the previous level." As a result, the people affected find themselves in an emergency situation that threatens their very existence. Some employees on leave of absence only receive wage substitution benefits for the first 45 days. Dismissed employees who were not previously employed for a certain minimum period of time do not receive any support at all.

Still many workers on leave even though production resumes

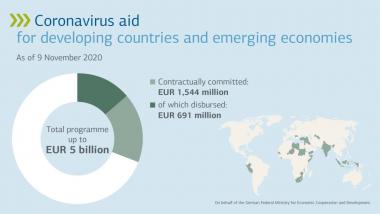

In April 2020, the Bangladeshi government launched four economic support packages totalling around EUR 7.3 billion to mitigate the impact of COVID-19 on the economy. With the emergency aid now launched at short notice, the German Federal Ministry for Economic Cooperation and Development (BMZ) is topping up the existing EU sector budget support of EUR 93 million by up to EUR 20 million. This grant to the national budget for 2020 not only makes it possible to re-finance wage substitution payments for released textile workers, but also provides support, at least in the short term, to those who are particularly hard hit by a dismissal: for example mothers who do not receive benefits after the birth of a child, or those women and men who have been employed by a company for less than a year.

From November onwards, they are to receive the equivalent of around EUR 30 per month, initially for a maximum of three months, and possibly more. To ensure that this money reaches its destination, it will be transferred electronically to the bank accounts of those concerned via appropriate government platforms. The relevant export associations in the textile sector provide monthly updated figures on the number of workers released or dismissed.

"Subsidy does not release employers from their obligations"

Some 215,000 workers benefit directly from the payments through the German contribution alone, but indirectly almost four times as many benefit from them: Not only the family members, but also the communities where the textile workers live, as well as transport companies, street traders and other local service providers. Without this rapid support and the resumption of production, lasting economic damage to Bangladesh's already small and fragile economy can be expected. But Anirban Kundu also makes it clear: "It is by no means the intention to release employers from their legal obligations to continue to pay wages. Rather, the aim is to ensure that the emergency aid reaches workers who are no longer entitled to statutory continued payment of wages, so that they can at least make up for some of their misery."