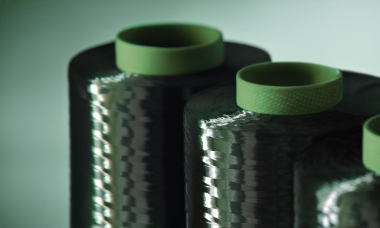

Teijin Carbon Europe GmbH receives ISCC PLUS certification

Teijin Carbon Europe has been awarded ISCC PLUS certification (Certificate Number: ISCC-PLUS-Cert-DE100-15897124). This ISCC PLUS certification covers Tenax™ Carbon Fiber produced at the Heinsberg-Oberbruch plant in Germany. This accreditation enables the Teijin Group to offer its customers sustainable products that contribute to circular economy. Teijin has selected the ISCC certification route as the International Sustainability and Carbon Certification (ISCC) is an independent organisation and the leading certification system in this field.

The ISCC PLUS certification is a voluntary system which administers the circular economy of chemicals, plastics, packaging, textiles and renewable raw materials. Raw materials which are made from sustainable source materials (e.g. via recycling or bio-based sources) are labelled with a sustainability declaration (country of origin of the raw material, quantity and type of sustainable raw material, user ID, etc.). This document then follows the product during further processing – even over several stages – until it is used by the end customer. If all partners in the chain are ISCC PLUS certified, the documents can be passed on clearly and reliably.

The Teijin Group is globally establishing a carbon fiber production and supply system based on ISCC PLUS certification. The attractiveness of ISCC PLUS certification for the Teijin Group is exemplified by the future production of sustainable carbon fibers. Teijin uses various chemical building blocks for the internal production of polyacrylonitrile. Conventional and sustainable raw materials can now be purchased and processed on the global market. In future, Teijin also intends to purchase materials that are obtained via recycling or directly based on a bio-based source.

These raw materials will then be processed into a sustainable polyacrylonitrile precursor. As the production processes are identical to those used in the conventional production of carbon fibers, the mechanical and chemical properties are identical. Based on the sustainability declaration, a clear mass balance is used to differentiate between sustainable and conventional products.

The Teijin Group obtained ISCC PLUS certification for carbon fiber and the polyacrylonitrile (PAN) precursor fiber produced at Teijin's Mishima Plant in Shizuoka Prefecture, Japan in June 2023, and began mass production of carbon fiber based on the certification in December of the same year. The Teijin Group benefits from this approach as customers are offered products that contribute to the circular economy or continue to use conventional raw materials.

Teijin Carbon Europe GmbH