Swedish innovation at ITMA Asia + CITME

In response to unprecedented market demand, BW Converting, a member of TMAS, the Swedish textile machinery association, will provide details about its new Baldwin TexChroma digital spray dyeing system at ITMA Asia + CITME in Singapore from October 28-31.

“We are excited to launch TexChroma because spray dyeing is the future and many of our customers are already seeing the benefits,” says Yiannis Vasilonikolos, BW Converting Sales Leader for Textiles, who has many years’ experience in textile dyeing technology. “We have conducted successful trials of TexChroma with pigment, reactive, acid and disperse dyes on both cotton and synthetic fibres.”

From production data to date, TexChroma can achieve savings in energy, dyes and chemicals of more than 30% compared to conventional continuous pad batch dyeing using steam, and up to 50% compared to exhaust reactive dyeing.

It also benefits from an advanced technology enabling reactive dyestuffs and alkali fixation chemicals to be mixed just seconds before spray application, in order to completely eliminate any ‘tailing and listing’– uneven dye application or colour variations.

The TexCoat® G4 Legacy

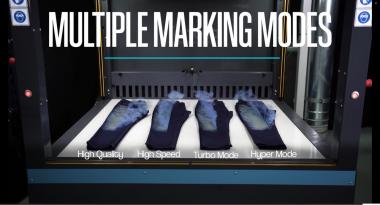

The introduction of TexChroma follows the runaway success of BW Converting’s Texcoat G4 finishing system in the past few years.

“TexCoat G4 spray technology was developed in Sweden from our off-set printing business, and we initially focused on installing units in Europe and the USA,” explains Vice President of Global Business Development for Textiles Rick Stanford.

“In the past two years, however, we have been very active in Asia, with 35 units sold – and many of these customers have been asking for a similar technology for the dyeing process.”

The first TexChroma will be installed at the plant of a very well-known Italian continuous dyer which is part of a larger textile manufacturing group, in order for it to be fully industrially tested before going into series production.

“Our first customer is close by our facility in Sweden, has the practical dyehouse skills we can learn from, and is a satisfied TexCoat G4 customer,” Stanford says. “We believe a major benefit of TexChroma will be in eliminating much rework which is common in dyehouses, but we’ve been very cautious about providing details on TexChroma too early. The dyeing process is unforgiving, and we must get it right the first time. The market has been ready for quite some time. And now, so are we.”

TMAS members in Singapore

In further new developments from TMAS members at the Singapore show, Kinna Automatic will provide details of its complete robotic lines for the production of pillows and duvets for the home furnishings sector and introduce the new Hector industrial sewing machine designed for the heavy duty circular and point stitching of filled textile components.

Eltex has made an important breakthrough on its EyETM tension monitoring system for the heat setting, tufting, warping and winding sectors, with the addition of electromagnetic brakes in combination with the latest advanced sensors. These enable tension variation to not only be detected, but automatically adjusted in real time during operation, rather than manually changed as previously.

The company’s ACT-R unit can further significantly reduce the selvedge yarn waste from the weft insertion systems of rapier weaving machines, while at the same time maintaining equal and steady tension across all pre-winders.

Advanced weaving control is also the bedrock of business for Vandewiele Sweden AB, which supplies weft yarn feeding and tension control units for weaving looms to the majority of the leading weaving machine manufacturers, as well as for retrofitting in working mills around the world The company will present its latest X4 yarn feeders with integrated accessory displays and has recently further strengthened its product portfolio with IRO Gaugepart modules. These are applied to tufting looms to determine the appearance of a carpet in terms of feel and structure.

Finally, the colarette machines of Svegea set the standard throughout Asia for the high speed production of tubular apparel components such as cuffs, collars and neck tapes and in Singapore the company will demonstrate its EC 50 and EC 200 with E-Drive II models, in addition to linked cutting systems.

AWOL Media for TMAS