Region of renewable raw materials: Central German Alliance for Bioplastics

The development of sustainable plastic solutions is rapidly gaining importance in light of global environmental pollution, dwindling fossil resources and ambitious climate protection targets. As part of the regional alliance RUBIO, which brings together 18 partners from central Germany and the Berlin-Brandenburg area, the bio-based and biodegradable plastic polybutylene succinate (PBS) was comprehensively investigated, starting with the raw material, through the manufacturing process, to industrial application. The aim was to evaluate the potential of PBS as an environmentally friendly alternative to polyethylene and to create the technological basis for new sustainable value chains. As a partner in the alliance, STFI was able to demonstrate that the bioplastic PBS is suitable for textile processing using the example of a net for straw bales.

The starting point: bioplastics sought as a substitute for PE

Increasing reports of macro and microplastics everywhere on earth, the finite nature of fossil re-sources, EU climate protection targets, and the call for CO2 reduction compel all stakeholders, especially the plastics industry, to act promptly. Bio-based and simultaneously biodegradable plastics ap-pear to be valuable raw materials for many applications, ranging from the packaging industry to the textile sector and agriculture. The aim of this project was comprehensive investigation of polybutylene succinate (PBS) from raw material to its industrial applicability. In order to qualify the biopolymer as a substitute for polyethylene (PE), its material properties were tested and evaluated with regard to their suitability for a wide range of applications.

The textile processing of the bioplastic PBS

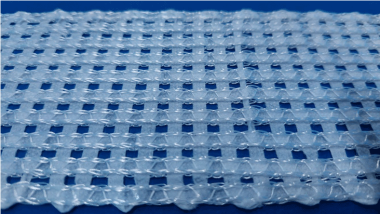

During project work, STFI main task was to explore opportunities and limits of technological processing of PBS materials (resins, film, nonwoven fabric, ribbons) into textile end products. Investigations were carried out on processing behavior of resins to nonwoven fabrics, followed by cutting processes into narrow ribbons, as well as studies on cutting and stretching PBS films and resins into ribbons. Subsequently, these ribbons were used to produce surfaces on knitting and weaving ma-chines. As a result, nonwoven fabrics, ribbons, and textile structures are available, which will be further optimized in subsequent projects. It has been possible to develop a knitted straw bale net that meets the requirements regarding mechanical properties of DLG (German Agricultural Society) for novel bio-based plastics.

Success and outlook

The results include spunbonded fabrics, ribbons and textile structures. A knitted straw bale net has been successfully developed that meets the requirements of the DLG (German Agricultural Society) for innovative bio-based plastics in terms of mechanical properties.

The focus for the future is on optimising textile production processes for the bioplastic PBS. The RUBIO2Value project was launched in December and will focus on applications such as injection-moulded reusable packaging, textiles and geotextiles, but also disposable packaging in upcoming studies by the consortium. At STFI, established textile processes are being converted to sustainable and renewable raw materials in order to use recycled or biodegradable materials for sustainable production.

Polybutylensuccinat polyethylene STFI Sächsische Textilforschungsinstitut e.V. agriculture bioplastic

Sächsisches Textilforschungsinstitut e.V. (STFI)