VDMA Position Statement: Textile machinery for a sustainable textile industry

In a position paper published, the companies organised in the VDMA Textile Machinery Association comment on the ambitious EU regulations and their national implementation for the sustainable and circular transformation of the textile and clothing industry.

The production of textiles requires a large number of resources, such as water, energy and chemicals. “The members of VDMA Textile Machinery support customers with products worldwide to utilise great potential already at the textile production stage to thereby reduce CO2 emissions“, explained Verena Thies, Deputy Chairwoman of VDMA Textile Machinery.

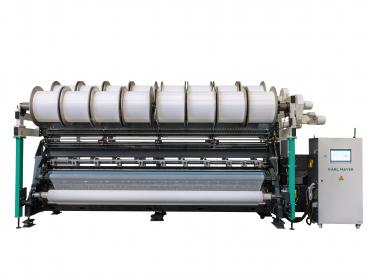

The position statement emphasises the importance of efficient processes, circular economy and binding rules for all market participants. Besides, the position paper summarises the status of textile-to-textile recycling processes as well as the framework conditions for reprocessing of recyclates. The companies of VDMA Textile Machinery develop processes and technologies for recycling and provide the technical prerequisites for the efficient reuse and recycling of textile raw materials, whether natural or man-made fibres.

The Executive Board of VDMA Textile Machinery stresses additionally, that the new EU regulations for circular economy and their national implementation must be designed with realistic targets, measurable effects and as little bureaucracy as possible. Furthermore, market surveillance is needed to ensure a level playing field for all market participants.

On behalf of the industry, the VDMA Textile Machinery Association calls for creating better location conditions in Germany and EU as a favourable environment for innovation und competitiveness for textile machinery manufacturing to significantly advance the sustainability of the textile industry: The Textile Machinery Association strongly emphasises the need for a wide range of low-cost green energy, which is essential for the implementation and sustainable use of recycling solutions in the manufacturing industry. The association also sees the positive shaping of location conditions (the potential for skilled labour, a reduction in bureaucracy, shorter approval periods, investment security and predictability as well as a reduction in the tax burden) as a decisive factor for supporting sustainable business in the highly competitive textile and clothing industry.

VDMA e. V.