A proposition for pioneers at ITMA

imogo is a new Swedish company formed by a team with long experience in textile processing technology. It is now boldly aiming to change the face of the textile manufacturing industry with its new Dye-Max spray dyeing technology, to be introduced to the market at ITMA 2019 in Barcelona.

While still at the prototype stage, and with a first full-scale line currently under construction and due to be demonstrated this Autumn before delivery, the DyeMax nevertheless promises to slash the use of fresh water, waste water, energy and chemicals by as much as 90% compared to conventional jet dyeing systems.

Spray cassettes

Its application unit consists of a closed chamber containing a series of spray cassettes with precision nozzles for accurate and consistent coverage, in combination with the patented imogo pro speed valve that controls the volume to be applied. The chamber is equipped with an exhaust system and droplet separator to ensure that the environment around the unit is free from particles.

“The spray cassettes are a key part in the Dye-Max line,” explains Imogo’s founding partner Per Stenflo. “There is one set of spray cassettes for each of the three separate dye dispersion feed lines and they can be easily exchanged without the need for tools in less than a minute. This allows for extremely fast changeovers between different colours without the need for cleaning. And because the spray cassettes are removable, all maintenance can be performed off line.

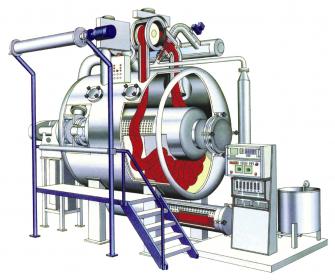

After applying the dye dispersion the fabric is rolled onto a shaft and moved to the autoclave for deep dye fixation via heat and pressure.”

The savings in treatment water the Dye-Max achieves are due to the extremely low liquor ratio of 0.5 litres per kilo of fabric Stenflo adds.

“At the same time, the low liquor ratio and the spray process require considerably less auxiliary chemistry to start with, and all of it is used in the process, which also greatly reduces the production of waste water, with only 20 litres being required for wash at changeovers. The low liquid content in the fabric meanwhile minimises the energy needed for fixation.”

The Dye-Max has a working speed of up to 50m/min with the practical speed determined by the fabric weight and application volume.

imogo

imogo