INDA: Clean Advocacy Summit in Washington D.C.

INDA held an Advocacy Summit in Washington, D.C. in partnership with ISSA’s, The Worldwide Cleaning Industry Association, 2024 Clean Advocacy Summit. Over the course of two days, INDA members took to the nation’s capital to convene, connect, and advocate for issues important to the nonwovens industry, meeting with the staff and elected officials in over a dozen congressional offices.

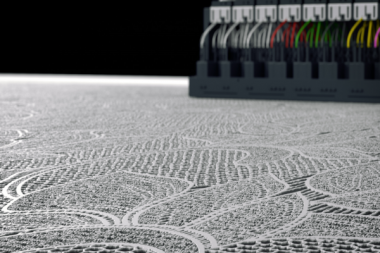

A key focus of these congressional meetings was education and support for the passage of the WIPPES Act (H.R.2964 / S.1350), the federal effort to implement consistent national Do Not Flush Labeling standards for non-flushable wipes. They also advocated for the renewal of the Miscellaneous Tariff Bill to provide tariff relief on items without domestic production as well as discussed various trade policy issues.

The advocacy summit portion of the event included panels on Wipes Policy, consumer education, international trade, plastics, and PFAS. Speakers included Dr. Laurie-Ann Agama, Acting Assistant U.S. Trade Representative for Textiles, James Willett, International Economist for the International Trade Administration, Sarah Sapirstein, federal lobbyist for the California Association of Sanitation Agencies, Lara Wyss, President of the Responsible Flushing Alliance, Jason Eberstein of the Plastics Industry Association, and Shawn Swearingen of the American Chemistry Council.