AFFIX Labs launches world’s first long-lasting surface treatment to kill the coronavirus

- Si-Quat by AFFIX Labs is a versatile anti-viral surface treatment that has been scientifically proven to last for months on any surface or textile while effectively killing the COVID-19 pathogen upon contact.

Helsinki - Leading chemical binding expert AFFIX Labs has harnessed its global experience in disease prevention to create the first long-lasting surface treatment proven to kill COVID-19. Si-Quat combines a safe and well-established disinfectant and a proprietary chemical binding technique, so that the active ingredient can kill viruses, including SARS-COV-2. Testing at Portugal’s Biochemistry Institute at the University of Lisbon proves that Si-Quat effectively kills the COVID-19 pathogens that it comes into contact with.

“Tragedies have unfolded across the globe, affecting different countries at varying degrees. The second waves of COVID-19 are just appearing on the horizon. This long-lasting surface treatment is a viable, accessible solution across cultures. By killing the COVID-19 pathogen on surfaces before it can infect people, the Si-Quat solution is a game changer. It can provide increased security and peace of mind to your communities, as well as your customers,” says Tom Sam, CEO of AFFIX Labs.

Si-Quat has been tested to kill 99.99% of microbes within minutes, while still being fully safe to touch. Proven to be effective for about a month on frequently touched surfaces, it is the longest lasting anti-viral surface treatment available to reduce the spread of the novel coronavirus. The product is non-corrosive, free from silver salts and heavy metal nanoparticles, and perfectly safe to touch.

Several major agencies around the globe have already accepted quaternary ammonium, the main ingredient in the surface coating, to be an effective surface treatment against the novel coronavirus, including the World Health Organization (WHO), the US Environmental Protection Agency, the American Chemistry Council (ACC) and the European Chemical Agency (ECHA).

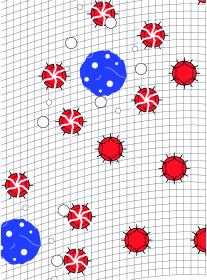

Si-Quat was invented in January 2020 by the AFFIX Labs’ Repeltec development team to specifically help combat the COVID-19 outbreak. The product is based on the trusted and safe disinfectant quaternary ammonium, which is chemically bound to align silane quaternary ammonium molecules (silane quats) in a highly effective manner. Positively charged nitrogen particles then actively attract viruses and bacteria, penetrating the membranes and killing them within minutes.

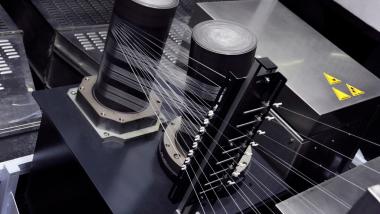

Rigorous testing has shown Si-Quat to adhere to almost any surface, performing as the most durable surface treatment commercially available. Due to its incredibly strong layer, the solution only wears down on surfaces after thousands of touches or multiple cleaning cycles. This means that on heavily used surfaces, such as door handles and counters, Si-Quat will be effective for about a month. On rarely touched surfaces like walls, it has the potential to protect for years. Since the product is incredibly easy to apply, technicians require minimal training and only basic protection. They simply have to brush or spray Si-Quat onto the surface and allow it to dry for 6 hours.

“Other sanitising solutions require reapplication to every surface several times daily, interrupting business operations. This results in additional costs and disruptions at a time when many companies are already struggling,” Sam explains. “By combining proven efficacy, safety and long durability, Si-Quat is emerging as an important weapon in the battle against the spread of COVID-19.”

AFFIX Labs has begun to roll out the distribution of Si-Quat across the globe, with new regions being serviced every week. It is currently looking for distribution partners in local markets.

The project leading to the development of Si-Quat included funding from the European Institute of Innovation and Technology, a body of the European Union, under the Horizon 2020 Framework for Research and Innovation.

EMG for AFFIX Labs