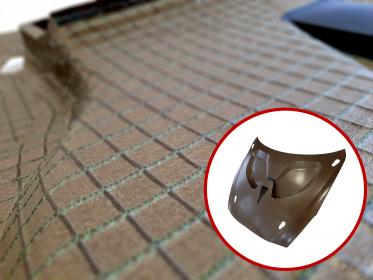

Drinking cups using chemically recycled polypropylene

Swiss dairy company Emmi is partnering with Borealis and Greiner Packaging to produce iced coffed drinking cups using chemically recycled polypropylene.

The cups are produced by Greiner Packaging and the chemically recycled material comes from Borealis, one of the world’s leading providers of advanced and circular polyolefin solutions based in Vienna, Austria.

Emmi, Switzerland’s largest milk processor is committed to climate protection and the circular economy. The dairy company has the stated goal to make all of its packaging 100% recyclable and is committed to various measures to promote circularity such as packaging that contains at least 30% recyclate by 2027.

From September 2021 Emmi will use at least 100 tonnes of plastic based on the recycled material each year. Chemical recycling renews plastic back to plastic creating recycled materials with a level of purity equivalent to fossil-fuel based PP and hence, fit for protective, food-safe and other demanding applications. In this way, Emmi is utilizing difficult to recycle feedstock preventing plastic waste that would be likely landfilled or incinerated. In the future, depending on the availability of suitable material, the amount of recycled plastic in packaging is to be further increased.

The new technology to recover the polypropylene is currently still in its infancy, where Greiner Packaging and Borealis are leading the way. Only limited quantities of chemically recycled polypropylene are currently available, and Emmi is one of only a few food manufacturers to have secured a share of the chemically recycled polypropylene plastic through its early commitment and long-standing collaboration with the development companies.

The chemically recycled material used for the cups consists entirely and solely of ISCC (International Sustainability & Carbon Certification) material, on a mass balance basis. Mass balance is a methodology that makes it possible to track the amount and sustainability characteristics of circular and/or bio-based content in the value chain and through each step of the process. This provides transparency ultimately also to the consumers, enabling them to know that the product they are buying is based on this renewable material.

Borealis