Lenzing leads Canopy ranking for sustainable wood procurement

“Hot Button Report”, the Canadian non-profit organization Canopy particularly highlights the innovative strength of the Lenzing Group, its active contribution to forest conservation and high level of transparency.

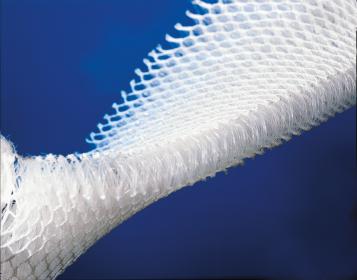

In the “Hot Button Report” issued by the Canadian non-profit organization Canopy, the Lenzing Group was once again rated number one in the world, thus confirming its role as the sustainability trailblazer in the textile industry. In this widely recognized ranking, Canopy grades the world’s 32 largest producers of wood-based fibers with respect to their success in achieving sustainable wood and pulp sourcing. Wood and the pulp derived from it are the most important raw materials underlying Lenzing’s sustainable production of cellulosic fibers.

“We are extremely proud of this top ranking. It underlines our leading position as a sustainability trailblazer in the manufacturing sector and in the fiber industry in particular. It gives our customers the confidence that we have created the right structures to prevent the sourcing and use of wood from ancient and endangered forests”, says Stefan Doboczky, CEO of the Lenzing Group. “Environmental protection and the prudent use of resources are an integral part of our responsibility to nature and society”, he adds.

Lenzing primarily convinced the non-profit organization Canopy this year thanks to its innovative strength used to promote the circular economy in the textile industry, its active contribution towards protecting the forests and preserving biodiversity as well as its high level of transparency in pulp sourcing.

Lenzing received a total of 26.5 points (up 3.5 points from the previous year) and was thus given the “light to mid green shirt” rating. This means that in using the wood-based cellulosic fibers produced by the Lenzing Group, there is only a very minimal danger that wood is derived from primeval forests and endangered forest areas. In the Wood and Pulp Policy published by Lenzing, the company confirms that it only sources wood and pulp from non-controversial sources.

Lenzing AG