MANTECO welcomes European Commissioner Elżbieta Bieńkowska

On March 7th, European Commissioner on the Internal Market, Industry, Entrepreneurship and Small and Medium-Sized Enterprises has been welcomed in Prato by the mayor Matteo Bittoni and by the Councilor for Productive Activities Daniela Toccafondi, together with the economic categories for a meeting organized by the Department of Economic Development with reference to the Fashion System.

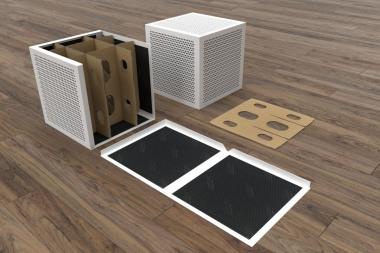

By the end of the meeting, the only company visit planned has followed, and brought to the Manteco headquarter. Manteco is a firm leader in the production of wool and recycled fabrics since 1943. Today led by Matteo and Marco Mantellassi, Manteco is able to value territory, sharing economy, sustainability, internationalization and the use of renewable energies – not only as an investment policy but also as a distinctive element for the identification of the company as an international reference point for the fashion textile sector.

The company visit was attended by European Commissioner Elzbieta Bienkowska, Justina Morek, member of the Commissioner's Cabinet, Beatrice Covassi, director of the Representation of the European Commission in Rome, Slawomir Tokarski, director for advanced and innovative manufacturing in the general direction of the internal market and European Commission industry, MEP Hon. Nicola Danti, dr. Alberto Biginelli, Councilor Daniela Toccafondi; The Mayor of Prato Matteo Bittoni, the Mayor of the Municipality of Montemurlo, Mauro Lorenzini.

The key topic of the meeting has been the circular economy – that is to consider very close to Manteco – along with some others explored such as the value of Made in Italy, the importance of a responsible approach to reuse and the need for a traceability system. Noteworthy the visit to the Manteco Archive, during which the focus has been on raw materials, with reference to the tradition and experience that today are perfectly combined with the strong innovative drive and creativity. Upon request of the European Commissioner, the corporate approach with a view to circular economy, km0 production system and how it fits into the productive district were also dealt with.

«I visited a textile company that recycles or reuses waste materials to produce wool of the highest quality: this is an excellent example of circular economy. The circular economy is an extremely interesting subject everywhere in Europe, because we are leaders in sustainability, and we want our children and ourselves to be able to live in a country that is livable in the future, so that's why it is worthwhile to show stories in Europe of success like this, which is a good practice that we are putting into practice, starting with the big industries and the energy-intensive ones » - Elzbieta Bienkowska -

GB Network Marketing & Communication