Elleti Group is back at Kingpins Show to present “Out of the blue impressions”

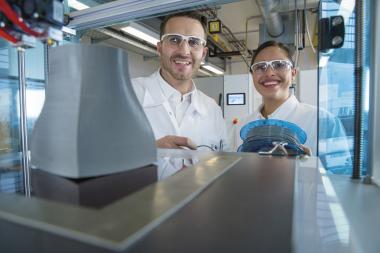

Long-established expertise and bold imagination define a state-of-the-art collection, providing an overview of the company’s complete denim services. From the idea development to the finished garment, the project was entirely envisioned, advanced and manufactured by the leading international group.

Mastery and creativity belong to Elleti Group’s character since the very beginning of its journey in the textile industry. Enhancing its unique approach, which also combines a solid tradition of excellence and the commitment towards innovation, the company returns once again to Kingpins Amsterdam Show with an exclusive new project to be presented at Transformatorhuis – Booth T7.

Inspired by six great artistic movements from the past century, Out of the blue impressions is the special capsule collection reimagining the timeless beauty of art through a unique style that breaks new ground. Twelve garments, featuring denim and more, are the result of the in-house R&D team effort and commitment to the development of one-of-a-kind solutions.

Every piece was envisioned and advanced according to a fresh and disrupting approach to art, resulting in unprecedented interpretations of much loved art periods to be realized on special canvases through specific techniques.

menabo Group