Beaulieu Fibres International at INDEX™20

Beaulieu Fibres International prioritizes collaborative product development & sustainable long-term partnerships

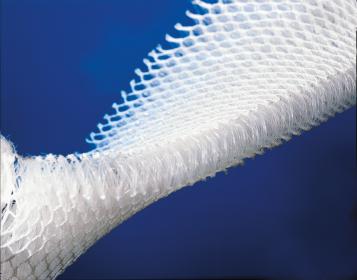

- Up & running: pilot line & new fibre line in Italy, BICO capacity for industrial fibres in Belgium

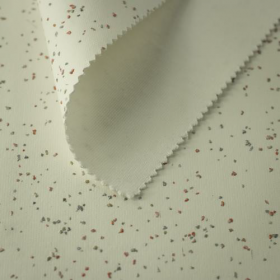

- Introducing new Meraspring for soft cushioned hygiene nonwovens

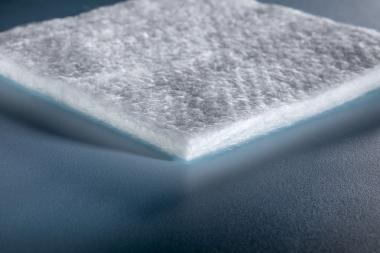

- Extended fibre range for filtration applications

- Stand 1340, INDEX™20, 31st March – 3rd April, Palexpo, Geneva

Beaulieu Fibres International, the leading European polyolefin and BICO fibre supplier, will announce at INDEX™20 completion of its pilot line in Terni, Italy, the start-up of the state-of-the-art multifunctional production line in Terni, and the new BICO line in Belgium. The company invites the Nonwoven sectors to join efforts in accelerating the development of innovative and sustainable solutions for a rapidly changing global market (Stand 1340).

New products are also on their way to show. For nonwoven converters serving the hygiene segment, Beaulieu Fibres International will unveil Meraspring to the European market at INDEX™20. The BICO-fibres are made with polyethylene (PE) in the sheath and polyethylene terephthalate (PET) in the core, and are the latest addition to the hygiene portfolio.

EMG for Beaulieu International Group