#Bemberg2020 – At Pitti Uomo

Bemberg™ supports the new generation of Italian sartorial style

In Florence, Bemberg™ presents an 8-pieces tailoring collection commissioned to and developed with students of the renowned Scuola Triennale di Alta Sartoria Maschile dell’Accademia Nazionale dei Sartori in Rome as well as with prominent lining manufacturers as Brunello S.p.A., Gianni Crespi Foderami S.p.A., Tessitura Marco Pastorelli S.p.A. and Manifattura Pezzetti Srl.

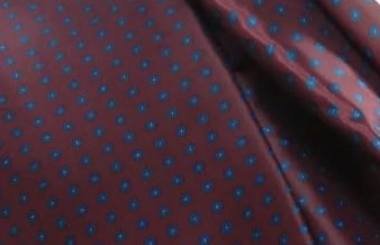

“We couldn’t have started the new year in a better and most promising way!” Says TAKESHI IITAKA, president of Asahi Kasei fibers Italia. The Japanese brand of regenerated cellulose fibers has tasked students at the Accademia Nazionale dei Sartori excellences. The designers of tomorrow created 8 contemporary clothing teaming up with prominent lining manufacturers that offered premium jacquard, striped and dotted materials in vivid colors that follow the seasonal trends. Yarn dyed options made unique by impactful contemporary designs that create interesting contrasts with the tailoring proposals.

The participation at Pitti is the first of a global tour pointing to some of the most cutting edge design innovations on planet Fashion. The next appointments include ISPO in Munich and Première Vision New York.

At each appointment the company will showcase a different aspect of its multitasking and sustainable imprint.