12 Composites Innovators to receive a JEC Innovation Award in Seoul next November 15, 2018

Twelve companies from eight different countries will receive a JEC Innovation Award at JEC Asia 2018. Asia-Pacific is an innovative region that sets the tone for all other regions of the globe. Once again, the JEC Innovation Awards highlight how composites bring solutions considering the new challenges in terms of efficiency, sustainability and life-cycle analysis.

This year, JEC Group awards innovations in the following categories: aerospace (structural and tooling), automotive, commercial vehicles, e-mobility, marine, railway, sports & leisure, infrastructure & civil engineering, industrial equipment, sustainability and additive manufacturing.

The ceremony will take place on Thursday November 15, 2018 at the COEX Center of Seoul (South Korea). Ida DAUSSY (Seo Hye-na), will host the ceremony in front of officials, manufacturers, scientists and composites professionals.

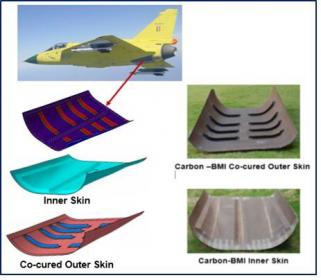

Category: AEROSPACE – STRUCTURAL

Winner: CSIR National Aerospace Laboratories (India)

Most of the composite structures for aircraft are made of carbon-epoxy composites, which can withstand a maximum service temperature of 130°C. As a consequence, carbon-epoxy materials cannot be used in hot zones like engine vicinity areas. The Aeronautical Development Agency (ADA) and CSIR-NAL took up the challenge of developing high temperature resistant composites for use in hot zones of light combat aircraft, which would result in significant weight and cost savings, as well as a considerable reduction in the meantime between failures (MTBF) due to thermal ageing.

The first task was to choose a material system with a service temperature of about ~ 200°C. During the material selection process, it was found that BMI resins are a relatively young class of thermosetting polymers. Hence, a carbon-BMI prepreg was selected due to a number of unique features including excellent physical property retention at elevated temperatures and in wet environments.

It was realized that weight savings and performance can be maximized using co-curing technology. This results in a large reduction of fabrication cycle times, costs and weight. Co-cured structures have fewer fasteners, which results in shorter assembly cycle times and also reduces sealing issues.

A prototype engine bay door assembly was built and tested at 180°C for flight certification. The engine bay door consists of an inner skin and co-cured outer skin assembly with eight transverse stiffeners. The stiffeners were designed with ‘J’ sections. The door size was 1.5 m length, 1 m width and 0.4 m overall depth. The co-cured door was developed using autoclave moulding. Two doors were installed in prototype aircraft and successfully flown.

AGENCE APOCOPE