Oerlikon Nonwoven at INDEX: Focus on nonwoven products

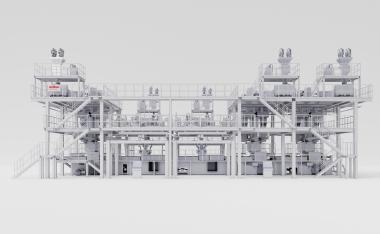

„Your reliable partner in the nonwoven industry“ – the slogan speaks for itself: Oerlikon Nonwoven is exhibiting at the world’s leading nonwovens trade fair – the INDEX in Geneva, Switzerland (October 19-22, 2021) – with one of the market’s broadest portfolios. The Neumünster-based systems constructor will be focusing on market- and customer-oriented system solutions for filtration, hygiene, medical, geotextile and other industrial applications. Trade fair visitors can delve deep into the company’s comprehensive product and process know-how both live at trade fair stand no. 2314 and via the INDEX online platform.

- Nonwovens for filtration, insulation and sorption applications

- Comprehensive spunbond portfolio

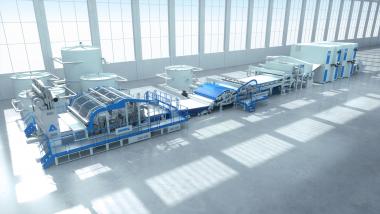

- Quality Sized Right-Technology: spunmelt systems for the hygiene and medical market

- Wipes using Oerlikon's Phantom technology

- Airlaid technology for sustainable nonwovens

Oerlikon