TINTEX @ Performance Days: 3 cutting-edge eco-performing innovations on show

- A naturally advanced collection, a cutting-edge coloration technology, and a brand-new collaborative business model.

- TINTEX stands out at PERFORMANCE DAYS, the functional fabric fair for the sourcing in sports, work and corporate wear.

- Performance Days, Munich, November 13th -14th, 2019 –booth C08 / hall C1

The leading jersey manufacturer brings a new holistic and sustainable approach spun from the company’s DNA and woven in the mission to create Naturally Advanced fabrics.

The WEME collection - A/W 20/21

The new statement collection goes beyond intellectual and spiritual individual needs to embrace a communal vision blurring ‘we’ and ‘me’, ‘conscious’ and unconscious’, responsible innovation and creativity. Developed around the concept sub-collections ID, Superego and EGO, the range comes in electric and active tones and combines smart ingredients and processes to drive innovation by harnessing the company’s unique dyeing and finishing expertise.

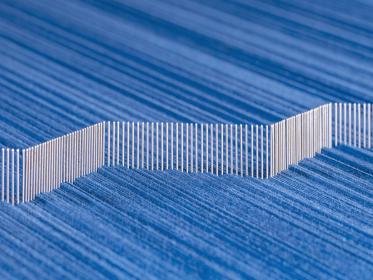

The new fabrics are made from a mix of new generation fibers that enhance free movement such as REFIBRA™ by Lenzing, Q-NOVA® by Fulgar and the unique GRS certified premium stretch ROICA™ EF. The smartcel™ powered ID sub-collection is defined by striped structures that simulate flaws on initially smooth and perfected surfaces and provides soothing, anti-inflammatory effects thanks to the inclusion of zinc oxide, provides soothing, anti-inflammatory effects. The “EGO” selection comes in rich purples, calm lilacs and feminine yellows and features natural fibers such as organic wool. The “Superego” is available in unique styles and colours, achieved thanks to Colorzen® and the Naturally Clean® finishing. Together these enhance the natural beauty of cotton and cellulosics eliminating harsh treatments and optimizing clean surfaces with vivid colors, and an exquisitely smooth hand feel. Transformed materials take such as ECOTEC® by Marchi&Fildi take the lead saving up to 77.9% in water compared with regular cottons.

COLORAU®

TINTEX’ cutting edge color technology which received the Sustainable Solution award in the May 2019 edition of Techtextil debuts in Munich. COLORAU® was created with a Portuguese consortium constituted by premium realities and gives life to responsibly colored fabrics with antimicrobial properties, using natural dyes extracted from different types of natural plants resources that do not use salt in the production.

COLORAU® uses only compounds of natural origin such as thyme, boldo, peppermint, chestnut and gambier in the production of functional and sustainable textiles in a variety of fibers such as cotton, lyocell and wool. An eco-efficient and low temperature surface treatment improves the affinity between the textile substrate and these natural compounds. The technology features a selection of “performing” extracts for appropriate color fastness to light and washing as well as color durability and antimicrobial functionality.

CO.LAB

TINTEX is proud to announce CO.LAB, a smart and collaborative business model and a totally new supply chain developed in coordination and with the support of C.L.A.S.S.. The first sustainable and PETA-Approved collections are 100% traceable without compromising on quality and style. As co-leader and founding actor, TINTEX has invited Becri, Confetil and Pedrosa & Rodrigues, 3 leading companies, each producing specialized garment styles. The new collections are:

- The ECOPERFORMER by TINTEX with Confetil collection meets the values of millennials and generation Z consumers. Sustainable, multitasking, gender neutral and designed to fit contemporary urban lifestyle. The collection comprises modern soft sports garment with fully transparent innovation values. The range flexes its muscles with the best sustainable and high-performative materials for comfort, ease and style. All selected fabrics are PeTA APPROVED VEGAN. Designed to win.

- ‘LEGACY H20’ by TINTEX with Becri is 100% traceable and focuses on responsible water-management.

- ‘SENSING SMARTS’ by TINTEX with Pedrosa & Rodrigues, a next-to-skin soft and sensual range of materials enhancing wellbeing and comfort while harnessing an innovative and responsible way of using chemical products for a greener and safest future.

GB Network Marketing & Communication