Epson auf Fespa 2024

Der Fokus des Epson Standes der diesjährigen Fespa (19.3. bis 22.3.) liegt auf dem Thema „Produktion personalisierter, individueller Produkte mittels Mikroproduktion“.

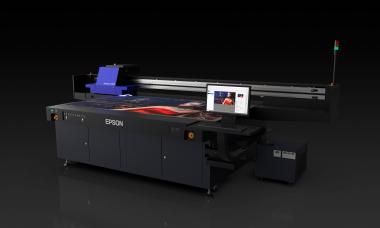

Auf seinem diesjährigen Stand zeigt Epson zum ersten Mal das DTG-/DTFilm-Einstiegsmodell, den SureColor F1000.

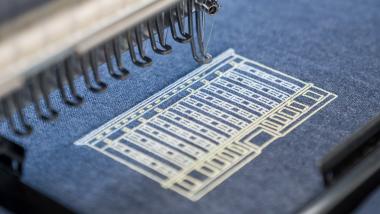

Der Epson SureColor-F1000 ist ein DTG-/DTFilm Hybriddrucker der Einstiegsklasse, der ohne Zwischenschritt sowohl auf dunkle als auch helle Textilien druckt. Der SC-F1000 verfügt über eine weiße Tinte und verarbeitet daher auch dunkle Textilien und Folien. Druckdienstleister können mit ihm Artikel wie T-Shirts, Kapuzenpullover, Taschen, Sweatshirts und Kissen produzieren. Er ist ebenfalls gut für jeden Anbieter von On-demand Druckdiensten geeignet.

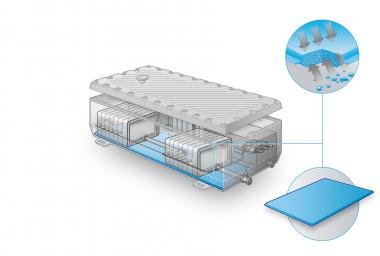

Zusammen mit dem SureColor F1000 wird der von Epson jüngst vorgestellte DTG-/DTFilm-Hybriddrucker SureColor F2200 präsentiert, der für Start-Ups und mittelständische Unternehmen entwickelt wurde, die ein hohes Maß an Flexibilität sowie kurze Produktionszeiten und präzise Reproduktionen erwarten. Der zur Umsetzung anspruchsvoller Designs auf einer Vielzahl unterschiedlicher Textilien entwickelte SureColor F2200 setzt auf die Epson PrecisionCore MicroTFP-Druckkopftechnologie. Damit erreicht er eine um bis zu 25 Prozent verbesserte Produktivität zu vergleichbaren Modellen.

EPSON DEUTSCHLAND GmbH