PERFORMANCE DAYS Fair with Topic: Still Physical – Your Success Story of 2020

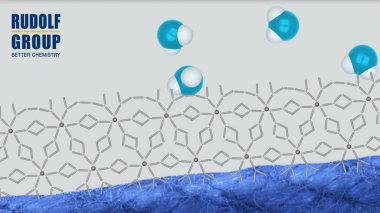

Contact restrictions, home office and altered daily lives – our lives in 2020 were radically changed. This was also the case for various sectors of the economy, including the textile and clothing industry. However, with crisis come opportunities and stimuli for change. Under the motto “Still Physical”, manufacturers recount their personal success stories in 2020 – the industry can look forward to a selection of sustainable materials curated exclusively by the PERFORMANCE FORUM Jury. Areas of focus: natural fibers that highlight wellbeing aspects, plant-based materials that make us strong and excite on an emotional level, bio-nylons and bio-based finishings that rethink function. “Still Physical – Your Success Story of 2020” will be on display online as the first of its kind within a trade fair week from 17 to 21 May 2020.

Transformation: Technology first?

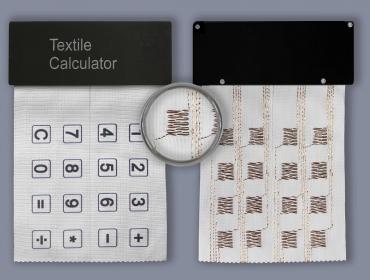

The pandemic has forced us into new, primarily digital forms of living and working. Our daily lives are characterised by home offices, home schooling and online meetings. The desire for real, physically perceptible experiences has grown incessantly within the last year. In the same context, people nowadays are strongly driven by technological progress – yet how far can we allow technological change to go and how do we wish to live in the future? Long before the pandemic, the trend towards self-monitoring and control of important bodily functions developed. The sports industry developed tools to measure levels of performance and monitor bodily functions with the goal of enhancing performance. Self-optimisation, body shaping and health promotion have become standard nowadays. Staying healthy and keeping fit are now social imperatives in our performance-oriented society. The pandemic has made us rethink, made us pause – with sustainable function still in focus, yet function needs to be rethought for the future, distancing ourselves from mere performance enhancement, and embracing clothing that facilitates people in feeling good.

Touch & Feel

In a visual, digital world, one sense has been forgotten: the sense of touch. Materials trigger completely different reactions, consciously or unconsciously. Moreover, the surface texture is also decisive in the functionality of a fabric, lending it its unique characteristics. In times of contact restrictions and lockdown, there is a need for a space for emotions, for regeneration and physical wellbeing. This is also reflected in the desire for appropriate apparel that leaves a pleasant sensation on the skin. Lightweight, warm and of a softer nature, plant-based fibers fulfil the desire for comfort and promote wellbeing.

We are physical – we are nature

How will we shape and adapt the post-pandemic textile and apparel industry? The Corona crisis once again reminds us of our existential bond with the natural world. While humanity fights against the spread of a deadly virus with social isolation, one thing is doing well: our planet. It is recovering from all the exhaust gases that are released into the air daily by cars and factories. There is a shift in focus towards taking time out in nature, whether in the form of a morning run, a mountain hike or a yoga session on the grass.

Your success story of 2020

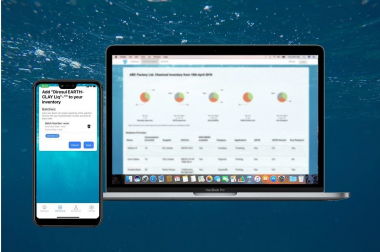

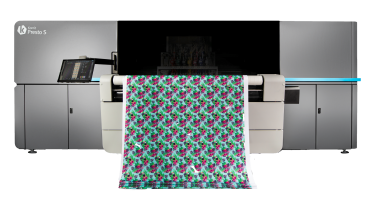

What has touched them? Which experiences have shaped their latest innovations? Does the crisis also present opportunities? The chance for something new, for a rethink, on an even more sustainable, more ecological path? Which highlights, which stories are worth communicating and where did the focus lie in 2020? Various material manufacturers already started to focus on sustainability and the cautious use of resources some time ago. Innovations in the areas of materials and in processing methods are the driving forces of the development towards more sustainability. However, we need to realign all processes and structures in our supply and production chains and adapt them to the needs of a resource-conserving, responsible industry. A pioneering example of such alignment was the decision of PERFORMANCE DAYS to only present sustainable materials at the PERFORMANCE FORUM from the November 2019 trade fair event onwards. Additionally, the setting-up of the new digital sourcing platform “THE LOOP” shows how technology can be implemented aside from material and processing innovations in such a way that our procedures and structures can be adapted to difficult conditions.

Informative & up-to-date: the digital trade fair week from 17 to 21 May 2021

As usual, the highlighted fabrics from the Focus Topic “Still Physical”, which the exhibitors have defined as their personal success stories, will be available shortly on the PERFORMANCE DAYS website highlighting all details and facets.

Performance Days trade fairs digital Functional textiles Sportswear Sustainability

PERFORMANCE DAYS