Kraig Biocraft Laboratories: Third Spider Silk Production Cycle

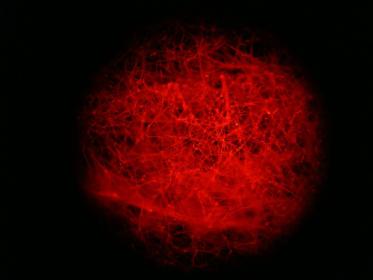

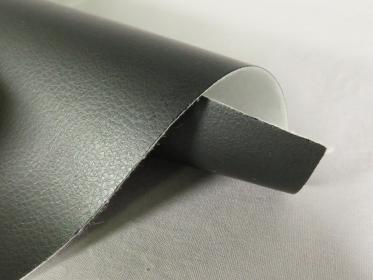

Kraig Biocraft Laboratories, Inc. announces that it has entered the rapid growth rearing phase for its third spider silk production cycle of the season. During this phase, the silkworms grow exponentially in preparation for spinning the Company’s proprietary recombinant spider silk cocoons.

Over the last week, the Company has taken steps to add additional production space to accommodate the rapidly growing silkworms during this phase. The Company continues to closely monitor the health and performance of the entire silkworm colony during this period of significant growth. Reports from the Company’s rearing team continue to show that the BAM-1 Hybrids are the most robust production strain that the Company has ever fielded.

As previously reported, the Company has adopted a batch-rearing process to minimize overcrowding and level loading the need for fresh, dry mulberry during the traditional rainy season. This approach is designed to further support silkworm colony health and ensure optimal rearing and cocooning conditions.

Kraig Biocraft Laboratories, Inc