eurolaser at FILTECH 2019

At FILTECH, eurolaser will demonstrate the advantages of a large-format laser system in the processing of filter material. The handling of the material from the roll is particularly comfortable with eurolaser's own conveyor system in combination with a feeding unit. At the FILTECH, eurolaser presents its L-3200 with a table size of 1,800 x 3,200 mm.

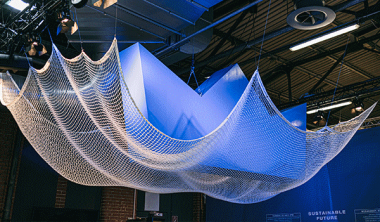

Large-format laser systems are ideal for cutting of filter material. The contactless process guarantees a constant cutting quality without tool wear. The table concept with extraction reduces dust and keeps the material in place at the same time. In addition, the thermal laser process ensures that when cutting synthetic textiles, the edges are sealed and thus protected from fraying. This makes subsequent processing much easier. The laser also allows fine details and filigree structures which cannot be produced by a knife.

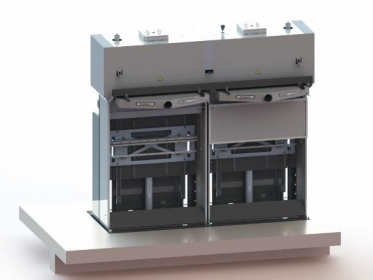

Conveyor – for all materials from the roll

Especially for all materials from the roll, eurolaser offers several of its systems as conveyor versions. In these versions, the surface of the processing tables consists of a stainless steel rod mesh. They are equipped with an automatic unwinding unit as fabric feed. The unwinding speed adapts to the retraction of the conveyor and the decreasing roll diameter. For very large and heavy rolls there is also a driven unwinding unit. Integrated laser projection lines indicate the correct position so that the roll change is fast and error-free. The remaining length capture ensures that there is always enough material left on the roll for the respective job.

For even more flexibility, there is space for additional tools or marking modules next to the laser. The motion system comes from the Swiss world market leader for digital cutters ZÜND. The machines are equipped with the Laserscout software suite, which contains the right software packages tailored to the application.