Hexcel provides HiTape® Dry Carbon Tapes for Madshus Skis

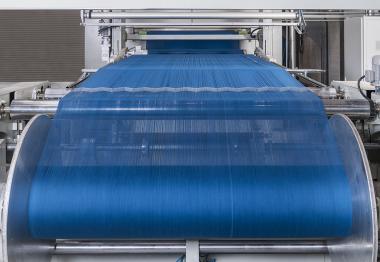

Hexcel is collaborating with Madshus, innovator in the world of cross-country skiing, on the engineering of a range ofdry carbon fiber tapes for Madshus’ acclaimed cross-country racing skies. Hexcel’s new HiTape® Dry Carbon Tapes improve the performance, manufacturing efficiency and surface finish of Madshus Skis.

“HiTape® gives us exactly what we need for our automated production processes - consistency and quality. In particular the exceptionally clean edges of the tapes, really makes a difference in our molding process and enhances the surface finish of the finished ski. We always aim for the highest levels of quality and Hexcel HiTape® helps us to deliver that.” concludes Bjørn Ivar Austrem, Technical Director, Madshus.

Hexcel’s new HiTape® Dry Carbon Tapes for Madshus Skis will be on display at ISPO Munich 2020, from 26 to 29 January.