REDES4VALUE: Recycled nylon fishing nets for industrial applications

- The companies UBE and ZIKNES, the University of Valencia, and the AIMPLAS Plastics Technology Centre are collaborating on this project, funded by IVACE+i Innovation with support from ERDF funds.

- Applications include packaging, agricultural covers, automotive components and large-scale 3D demonstrators.

- Collaboration with Sea2See ensures the supply of recovered nets from Ghana and strengthens the project’s circular value chain.

The abandonment of fishing nets in seas and oceans is one of the most persistent environmental problems. In response to this situation, the REDES4VALUE project works to recover and recycle disused fishing nets, transforming them into new sustainable, high value-added products such as recycled nylon, films for packaging and agricultural covers, automotive components, and large-format parts produced by additive manufacturing. These developments are achieved through innovative mechanical and chemical recycling processes, combined with reactive extrusion technologies.

This initiative, funded by the Valencian Institute of Competitiveness and Innovation (IVACE+i) and ERDF funds, brings together a consortium formed by AIMPLAS (Plastics Technology Centre), UBE, ZIKNES and the University of Valencia. Their shared objective is to close the life cycle of polyamides and reduce marine pollution through innovative, industry-ready solutions.

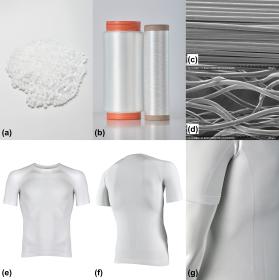

Although many nets are made of polyethylene or polypropylene, the project focuses on polyamide nets, a material with great potential for chemical recycling. Its molecular structure allows the recovery of monomers such as caprolactam, enabling the production of new polyamides with properties virtually identical to those of virgin materials.

‘We are achieving optimised conditions for depolymerising fishing nets and recovering monomers with purities above 95% in some laboratory-scale streams, and over 80% at pilot scale”. This will allow us to repolymerise and obtain new polyamides with quality equivalent to virgin material,’ explains Nairim Torrealba, a researcher in Chemical Recycling at AIMPLAS.

Recycled polyamides are intended for sectors such as packaging, agriculture, automotive and 3D printing. Companies such as UBE are already analysing their commercialisation and ZIKNES is adapting its equipment to validate large-format parts. Initial applications include packaging films, agricultural covers, automotive components and large-scale 3D demonstrators.

‘These materials have immediate industrial applications and a clear sustainability advantage over conventional polyamides. These solutions not only reduce dependence on virgin raw materials, but also open up new opportunities for industry in terms of sustainability and the circular economy,’ said Torrealba.

Disruptive technology and international collaboration

REDES4VALUE is advancing in processes such as hydrothermal depolymerisation, ionic liquid-assisted solvolysis and reactive extrusion, as well as comprehensive life cycle and feasibility assessments. One of the main challenges of the project is the treatment of highly degraded nets with a high presence of impurities, but the results are very promising.

Collaboration with the Sea2See brand has ensured access to fishing nets recovered in Ghana since 2019 and has been key to structuring the project’s circular value chain from the waste source. ‘Without this supply of material, it would not be possible to move forward. The nets that arrive from Ghana are essential for validating the processes and obtaining real results,’ said Torrealba.

Consortium and next steps

The project involves AIMPLAS, which is responsible for chemical recycling tasks, UBE for scaling and repolymerisation, ZIKNES for 3D printing validation, and the MATS group at the University of Valencia (MATS-UV) for solvolysis and kinetics studies. ‘Our goal is to consolidate a chemical recycling line that can be applied to complex waste and demonstrate that it is a real and necessary solution,’ concluded Torrealba.

This initiative is funded by the Valencian Institute of Competitiveness and Innovation (IVACE+i), through the Strategic Cooperation Projects programme in its 2024 call for proposals, with co-financing from the European Regional Development Fund (ERDF).

AIMPLAS, Plastics Technology Centre