Texworld Apparel Sourcing Paris

Nearly 8,000 international visitors came to meet the 1,300 exhibitors at Texworld Apparel Sourcing Paris. This year's event was enhanced by a boldly designed showcase in the heart of Paris.

The offer was broader, more diversified and more accessible. Despite increasing requirements in the industry, visitor numbers remained stable. It was on these two objective notes that the latest edition of the Texworld and Apparel Sourcing Paris trade shows for the fashion industry came to a close, held from 5 to 7 February 2024 at the Paris Expo Porte de Versailles. During these 3 days, nearly 8,000 visitors came to meet 1,300 weaving and clothing companies from 25 countries on the two levels of Hall 7 (7.2 and 7.3).

Visitors: a Euro-Mediterranean Top 5

This unprecedented concentration of international companies in Europe, which exceeds in number that of February 2019, is a reminder of the central role of European markets for the global fashion industry. This position is confirmed by the weight of buyers from the Euromed zone in the visitor structure: Top 5 is concentrated around buyers from France (20% of the total, up sharply on 2023), the UK (8.3%), Italy (7.9%), Turkey (7.2%) and Spain (6.8%). This Parisian event is proving to be an essential point of contact between designers, buyers and suppliers of fabrics or finished products.

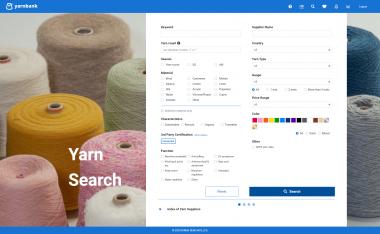

Making the offer ever more accessible “Despite the slowdown in the clothing market, Europe remains a major market for textile and finished goods manufacturers" explains Frédéric Bougeard, President of Messe Frankfurt France. “For some players, it is becoming a strategic market to offset the uncertainties weighing on the Russian and American markets" he continues. Our mission is to fulfill our role as a market place, to adapt to these changes and to make the international offer more and more accessible." The February event also highlighted near sourcing. Nine Ukrainian companies grouped together under the banner of the Ukrainian Association of Textile and Leather Industry Companies (Ukrlegprom), as well as Bulgarian, Italian and Dutch companies, were able to take advantage of the show's visibility to include their expertise in the sourcing plans of French and European buyers.

Texworld Apparel Sourcing Paris, a new name for our trade fairs

Reflecting the adaptation of Messe Frankfurt France's strategy to changes in the market, Texworld Evolution Paris is changing its name to Texworld Apparel Sourcing Paris. This move reflects developments in fashion sourcing and the expansion of brand universes. A growing number of buyers now want to be able to select materials, while also sourcing finished products directly to complement collections or expand their range. The new name is accompanied by a new dual baseline - Weaving the future; sourcing I business I solutions - to underline these developments and reinforce the fairs' service-led positioning.

From 1 to 3 July 2024 at Porte de Versailles

This new signature will be fully expressed at the next edition of Texworld Apparel Sourcing Paris, including Avantex and Leatherworld, which will take place from 1 to 3 July 2024 in Hall 7 (7.2 and 7.3) of the Paris Expo Porte de Versailles. The show, which will remain the same size and offer a more selective range of products, will reflect this convergence between textiles and finished products. This session will also have no interaction with the Paris 2024 Olympic Games, which are due to open on 26 July, three weeks after Texworld Apparel Sourcing Paris

Messe Frankfurt