"After all, a spaceship is not made off the peg."

Interview with vombaur - pioneers in special textiles

Technical narrow textiles, custom solutions, medium-sized textile producer and development partner for filtration textiles, composite textiles and industrial textiles: vombaur. Digitalisation, sustainability, energy prices, pioneering work and unbroken enthusiasm – Textination spoke to two passionate textile professionals: Carl Mrusek, Chief Sales Officer (CSO), and Johannes Kauschinger, Sales Manager for Composites and Industrial Textiles, at vombaur GmbH, which, as well as JUMBO-Textil, belongs to the Textation Group.

If you look back at your history and thus to the beginnings of the 19th century, you will see a ribbon manufactory and, from 1855, a production of silk and hat bands. Today you produce filtration textiles, industrial textiles and composites textiles. Although you still produce narrow textiles today, the motto "Transformation as an opportunity" seems to be a lived reality at vombaur.

Carl Mrusek, Chief Sales Officer: Yes, vombaur has changed a few times in its almost 220-year history. Yet the company has always remained true to itself as a narrow textiles manufacturer. This testifies to the willingness of the people in the company to change and to their curiosity. Successful transformation is a joint development, there is an opportunity in change. vombaur has proven this many times over the past almost 220 years: We have adapted our product portfolio to new times, we have built new factory buildings and new machinery, we have introduced new materials and developed new technologies, we have entered into new partnerships – as most recently as part of the Textation Group. We are currently planning our new headquarters. We are not reinventing ourselves, but we will go through a kind of transformation process with the move into the brand new, climate-friendly high-tech space.

Could you describe the challenges of this transformation process?

Johannes Kauschinger, Sales Manager for Composites and Industrial Textiles: A transformation usually takes place technically, professionally, organisationally and not least – perhaps even first and foremost – culturally. The technical challenges are obvious. Secondly, in order to manage and use the new technologies, appropriate expertise is needed in the company. Thirdly, every transformation entails new processes, teams and procedures have to be adapted. And finally, fourthly, the corporate culture also changes. Technology can be procured, expertise acquired, the organisation adapted. Time, on the other hand, cannot be bought. I therefore consider the greatest challenge to be the supply of human resources: In order to actively shape the transformation and not be driven by development, we need sufficient skilled workers.

Visiting your website, the claim "pioneering tech tex" immediately catches the eye. Why do you see your company as a pioneer, and what are vombaur's groundbreaking or pioneering innovations?

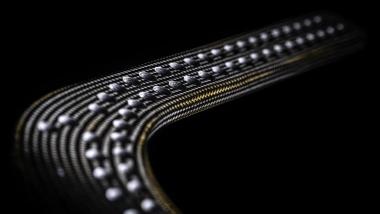

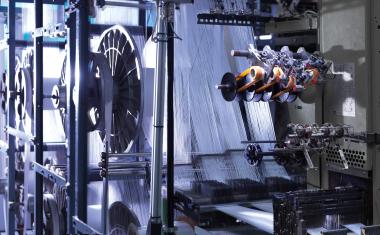

Carl Mrusek: With our unique machine park, we are pioneers for seamless circular woven textiles. And as a development partner, we break new ground with every order. We are always implementing new project-specific changes: to the end products, to the product properties, to the machines. It happens regularly that we adapt a weaving machine for a special seamless woven shaped textile, sometimes even develop a completely new one.

With our young, first-class and growing team for Development and Innovation led by Dr. Sven Schöfer, we repeatedly live up to our promise of "pioneering tech tex" by developing special textile high-tech solutions with and for our customers. At the same time, we actively explore new potentials. Most recently with sustainable materials for lightweight construction and research into novel special filtration solutions, for example for the filtration of microplastics. A state-of-the-art textile technology laboratory is planned for this team in the new building.

The development of technical textiles in Germany is a success story. From a global perspective, we manage to succeed with mass-produced goods only in exceptional cases. How do you assess the importance of technical textiles made in Germany for the success of other, especially highly technological industries?

Carl Mrusek: We see the future of industry in Europe in individually developed high-tech products. vombaur stands for high-quality, reliable and durable products and made-to-order products. And it is precisely this – custom-fit products, instead of surplus and throwaway goods – that is the future for sustainable business in general.

What proportion of your production is generated by being project-based as opposed to a standard range, and to what extent do you still feel comfortable with the term "textile producer"?

Johannes Kauschinger: Our share of special solutions amounts to almost 90 percent. We develop technical textile solutions for our customers' current projects. For this purpose, we are in close contact with the colleagues from our customers' product development departments. Especially in the field of composite textiles, special solutions are in demand. This can be a component for space travel – after all, a spaceship is not manufactured off the peg. We also offer high-quality mass-produced articles, for example in the area of industrial textiles, where we offer round woven tubulars for conveyor belts. In this sense, we are a textile producer, but more than that: we are also a textile developer.

In August, Composites Germany presented the results of its 21st market survey. The current business situation is viewed very critically, the investment climate is becoming gloomier and future expectations are turning negative. vombaur also has high-strength textile composites made of carbon, aramid, glass and hybrids in its portfolio. Do you share the assessment of the economic situation as reflected in the survey?

Carl Mrusek: We foresee a very positive development for vombaur because we develop in a very solution-oriented way and offer our customers genuine added value. This is because future technologies in particular require individual, reliable and lightweight components. This ranges from developments for the air taxi to wind turbines. Textiles are a predestined material for the future. The challenge here is also to offer sustainable and recyclable solutions with natural raw materials such as flax and recycled and recyclable plastics and effective separation technologies.

There is almost no company nowadays that does not use the current buzzwords such as climate neutrality, circular economy, energy efficiency and renewable energies. What is your company doing in these areas and how do you define the importance of these approaches for commercial success?

Carl Mrusek: vombaur pursues a comprehensive sustainability strategy. Based on the development of our mission statement, we are currently working on a sustainability declaration. Our responsibility for nature will be realised in a very concrete and measurable way through our new building with a green roof and solar system. In our product development, the high sustainability standards – our own and those of our customers – are already flowing into environmentally friendly and resource-saving products and into product developments for sustainable projects such as wind farms or filtration plants.

Keyword digitalisation: medium-sized businesses, to which vombaur belongs with its 85 employees, are often scolded for being too reluctant in this area. How would you respond to this accusation?

Johannes Kauschinger:

We often hear about the stack crisis at the present time. Based on this, we could speak of the stack transformation. We, the small and medium-sized enterprises, are transforming ourselves in a number of different dimensions at the same time: Digital transformation, climate neutrality, skilled labour market and population development, independence from the prevailing supply chains. We are capable of change and willing to change. Politics and administration could make it a bit easier for us in some aspects. Key words: transport infrastructure, approval times, energy prices. We do everything we can on our side of the field to ensure that small and medium-sized enterprises remain the driving economic force that they are.

How do you feel about the term shortage of skilled workers? Do you also take unconventional paths to find and retain talent and skilled workers in such a specialised industry? Or does the problem not arise?

Carl Mrusek: Of course, we are also experiencing a shortage of skilled workers, especially in the industrial sector. But the development was foreseeable. The topic played a major role in the decision to move together with our sister company JUMBO-Textil under the umbrella of the Textation Group. Recruiting and promoting young talent can be better mastered together – for example with cross-group campaigns and cooperations.

If you had to describe a central personal experience that has shaped your attitude towards the textile industry and its future, what would it be?

Johannes Kauschinger: A very good friend of my family pointed out to me that we live in an area with a very active textile industry, which at the same time has problems finding young talents. I visited two companies for an interview and already on the tour of each company, the interaction of people, machines and textiles up to the wearable end product was truly impressive. In addition, I was able to learn a profession with a very strong connection to everyday life. To this day, I am fascinated by the wide range of possible uses for textiles, especially in technical applications, and I have no regrets whatsoever about the decision I made back then.

Carl Mrusek: I came into contact with the world of textiles and fashion at a young age. I still remember the first time I went through the fully integrated textile production of a company in Nordhorn with my father Rolf Mrusek. Since then, the subject has never left me. Even before I started my studies, I had made a conscious decision to pursue a career in this industry and to this day I have never regretted it, on the contrary. The diversity of the special solutions developed in the Textation Group fascinates me again and again.

vombaur is a specialist for seamless round and shaped woven narrow textiles and is known throughout the industry as a development partner for filtration textiles, composite textiles and industrial textiles made of high-performance fibres. Technical narrow textiles from vombaur are used for filtration – in the food and chemical industries, among others. As high-performance composite materials, they are used, for example, in aircraft construction or medical technology. For technical applications, vombaur develops specially coated industrial textiles for insulation, reinforcement or transport in a wide range of industrial processes – from precision mechanics to the construction industry. The Wuppertal-based company was founded in 1805. The company currently employs 85 people.

Sectors

- Aviation & Automotive

- Sports & Outdoor

- Construction & Water Management

- Safety & Protection

- Chemistry & Food

- Plant construction & electronics

- Medicine & Orthopaedics

vombaur narrow textiles Technical Textiles INTERVIEW Textation Composites Filtration textiles

Textination