Evidence-based verification in recycled cotton sourcing

Hong Kong–based New Focus Textiles is adopting Haelixa’s Swiss DNA traceability technology to strengthen trust and transparency in recycled cotton production.

Haelixa, the Swiss-based global leader in DNA-based traceability, has enabled New Focus Textiles to provide forensic proof of recycled cotton content across its textile-to-textile manufacturing operations. This marks a significant move towards evidence-based verification in recycled material sourcing, addressing one of the main credibility gaps in the circular materials market.

DNA-based forensic traceability for recycled cotton

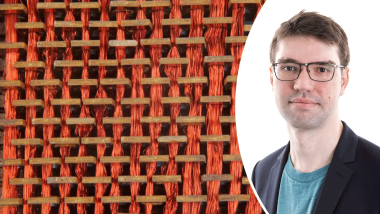

Haelixa’s DNA marker is applied directly to post-industrial and post-consumer waste, before shredding, staying intact through New Focus Textiles’ mechanical recycling process. The non-toxic DNA marker, which is derived from Swiss mountain herbs, is a permanent tag, and cannot be removed or copied, remaining embedded throughout spinning, weaving, dyeing, and finishing.

At any point, the material can be tested in an accredited laboratory using a simple PCR analysis to confirm origin and verify the presence of recycled content. This method provides physical proof of the recycled fibre identity, going beyond certification schemes that rely on documentation and chain-of-custody declarations.

Strengthening supply chain assurance

New Focus Textiles produces GRS-certified recycled cotton fabrics from post-industrial and post-consumer feedstock under its T2T™ (Textile-to-Textile) programme. The integration of Haelixa’s DNA-based traceability ensures each recycled batch is scientifically identifiable and can be aligned with digital records on platforms such as TextileGenesis, enhancing material transparency at supplier, auditor, and brand level.

Preparing for regulatory compliance

The system supports upcoming EU Digital Product Passport requirements and wider regulatory scrutiny over green claims. It reduces reputational and compliance risk for brands that prioritise recycled materials.

New Focus Textiles